The Condition Assessment Programme (CAP) is an expertise on the technical ship’s condition independent from the classification. Depending on the request, CAP assessment may include the actual technical condition of hull, machinery, electrical installation, and cargo related system. It is an independent and thorough verification to rate the actual condition of the ship, based on detailed inspection and function testing, thickness measurements and strength calculation and performance testing.

The CAP is applicable to oil tankers and bulk carriers of 15 years of age and above, and may well be used for ships at other ages and for other types of ships.

Purpose

The purpose of CAP is to provide applicants with a document and statement of ship’s actual condition such as structural strength, machinery, and maintenance of ship’s life, etc., which could be used towards cargo owners and/or authorities in connection with entry into new charters or renewal of existing ones beyond expire dates.

The main purpose of CAP is to evaluate and report the vessel’s condition above minimum class standard. The scope for CAP is more comprehensive than for class surveys with respect to extent and analysis of thickness measurements, structural strength evaluation, and reporting. Although CAP inspections may be carried out at the same time with class surveys, and a joint CAP/Class team may be onboard, CAP is reported completely separate.

Benefits of CAP

- Provides an independent evaluation of the condition of your ship.

- Helps you demonstrate the operational reliability of your ships, regardless of their age.

- Leads to preferential chartering opportunities and the potential for increased earnings.

- Helps in the early identification of deficiencies, maximizing on-hire time and reducing unplanned maintenance.

- Assists in maximising residual asset value.

Composition of CAP

CAP consists of two modules, one is CAP for hull structures (HCAP) and the other is CAP for machinery/cargo systems (MCAP).

- HCAP is to include check of documents and records, overall, internal and close-up surveys, thickness measurements and analysis, as well as strength assessment including longitudinal strength calculations, re-assessment of scantlings and fatigue strength assessment.

- MCAP includes a check of documents and records, an overall survey of machinery/cargo systems, function test, oil sample analysis and vibration measurement.

Scale of Rating

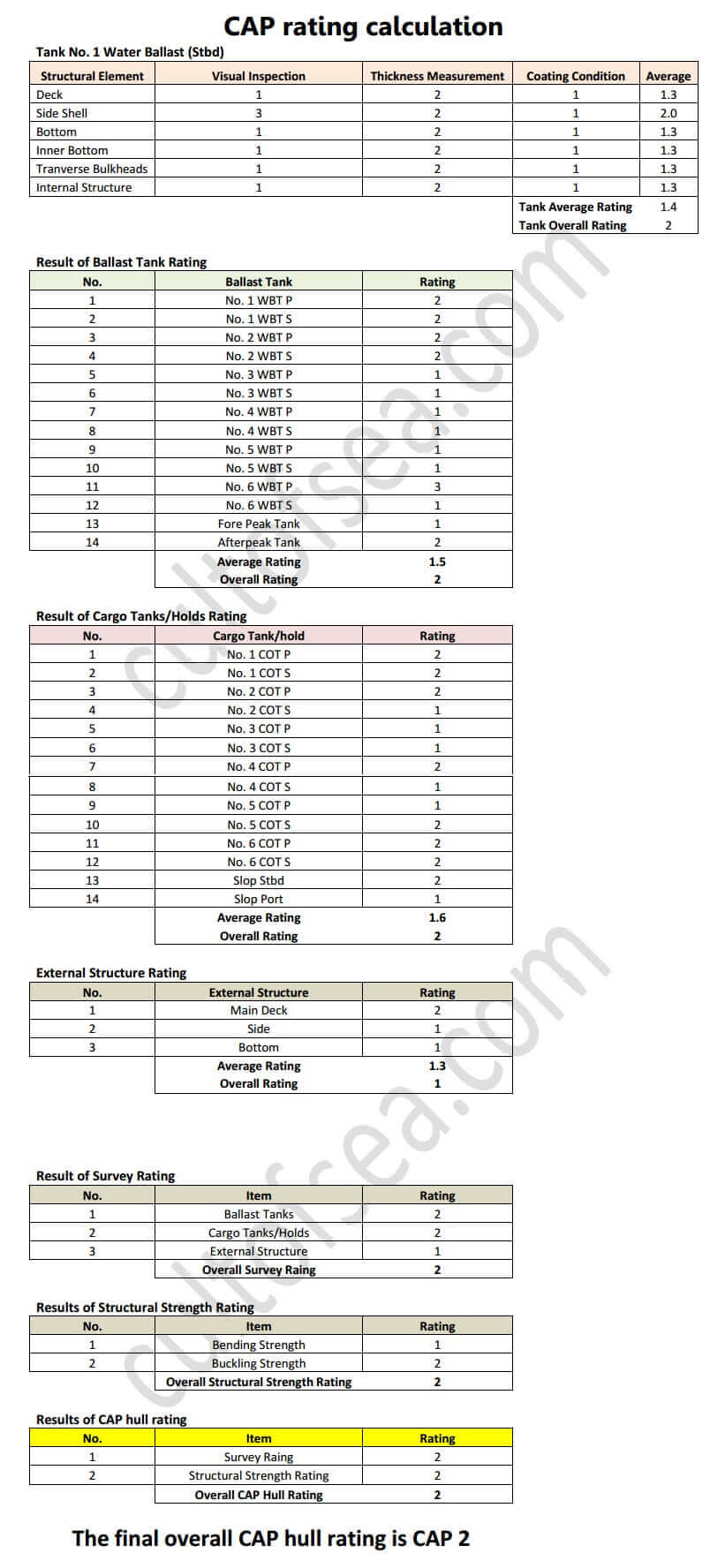

CAP rating has to be justified basing on the actual technical condition of the ship. CAP rates the vessel in accordance with a rating scale from 1 (very good) to 4 (poor).

The results of condition assessment are clearly identified and the definitions corresponding to each rating are indicated below.

CAP-HULL RATING

- Rating Level 1: “Very Good Condition”

Items examined and measured found with only superficial reductions from “as new” or current rule scantlings. No maintenance or repair required. - Rating Level 2: “Good Condition”

Items examined and measured found to have deficiencies of a minor nature not requiring correction or repair and/or found to have all thicknesses significantly above class limits. - Rating Level 3: “Satisfactory Condition”

Items examined and measured either found to have deficiencies, which do not require immediate corrective action or found to have thicknesses, which although generally above class renewal levels, do exhibit substantial corrosion. - Rating Level 4: “Unsatisfactory Condition”

Items examined and measured either found to have a deficiency or deficiencies which may affect the ship’s potential to remain in class, or found to have, in some areas, thicknesses which are at or below the class renewal levels.

CAP-MACHINERY/CARGO SYSTEM RATING

- Rating Grade 1: “Very Good Condition”

Items and systems examined and function tested, found with no deficiencies affecting safe operation and/or performance. Documentation and maintenance practices considered good. No maintenance or repair required. - Rating Grade 2: “Good Condition”

Items and systems examined and function tested, found with some minor deficiencies which do not affect safe operation and/or normal performance.Documentation and maintenance practices considered adequate. No immediate maintenance or repair considered necessary. - Rating Grade 3: “Satisfactory Condition”

Items and systems examined and function tested, found with deficiencies not affecting safe operation and/or performance. Documentation and maintenance practices considered to be of a minimum standard. Some maintenance and repair may be considered necessary. - Rating Grade 4: “Unsatisfactory Condition”

Items and systems examined and function tested, found with deficiencies significantly affecting operation and/or performance. Documentation and maintenance practices considered inadequate. Maintenance and repair required to reinstate serviceability.

After the completion of the CAP, the certificate of CAP indicating the ship’s comprehensive rating (Overall Rating for CAP-HULL and/or CAP-MACHINERY / CARGO SYSTEM) is issued.

Condition Assessment Programme for Hull Structures (HCAP)

General requirements

Condition Assessment Programme for Hull Structures (HCAP) is to have a ship judged based on the actual condition of the hull structure, in general, HCAP is to include check of documents and

records onboard the ship, visual inspection of hull structural members, thickness measurement and analysis of TM, strength calculation and scale of rating.Hull inspection is normally to be carried out in dry dock.

The following documents and records are to be checked prior to the commencement of CAP survey:

- Valid certificates of the ship (statutory certificate and class certificate)

- Vessel repair history of the ship (including alterations or modifications, properties of deficiencies and repair methods)

- Vessel survey records of the ship (special survey, annual survey, intermediate survey and docking survey)

- Latest report of thickness measurement

- Previous CAP reports, if any.

Plans and documents required for strength assessment of hull structures:

- General Arrangement

- Shell expansion

- Transverse mid-section plan

- Loading manual

- Construction profile, including bulkhead

- Records of thickness measurement at the time of assessment and other necessary plans.

The hull items assessed are:

- Ballast tanks

- Void spaces

- Cargo tanks

- Hull external structure

Structural strength

Each tank/space assessment is based on ratings of the main structural elements i.e. fore transverse bulkhead, aft transverse bulkhead, side shell, longitudinal bulkhead, deck (deckhead), bottom, internal structure. Strength assessment of hull structures consists of three parts, i.e. longitudinal strength calculation and fatigue strength assessment (optional). The overall rating for each tank/space/area is based on the overall structural/survey average rating of each structural element. The main deck, bottom and ship sides are to be rated in a similar way as tanks/spaces.

Thickness measurement

Thickness measurement is to be carried out by a recognized thickness measurement company under the direction of CAP inspector.

The main purpose of the analysis of thickness measurements is to establish the extent of general corrosion for each structural element to be rated. A statistical analysis of thickness

diminutions will be carried out against original “as-built” scantlings.

Visual assessment of structural condition

The purpose of a visual inspection is to assess the extent of defects and local corrosion (including pitting, grooving, edge corrosion).

Void spaces are to be surveyed at least in the scope of the overall inspection. All fatigue critical details i.e. details identified in fatigue assessment calculations are to be close-up surveyed.

The visual inspection is divided into items:

- Cracking

- Local corrosion (including pitting corrosion, grooving corrosion and edge corrosion)

- Deformation

- The condition of anodes as applicable.

- Any other local defect.

The visual inspection rating is carried out based on the result of the above inspection. In general, the lowest of the cracking, local corrosion and deformation rating is decisive towards the final result of visual inspection rating.

Condition Assessment Programme for Machinery (MCAP)

General requirements

MCAP is to include a check of documents and records, visual inspection, function test, collection and measurement of machinery parameters, vibration measurement, oil sample analysis and rating.

The items of inspection for MCAP include main engine/generating set prime mover, propulsion system, boiler and pressure vessel, piping system and machinery piping system, electric/automatic

system, deck machinery and liquid cargo machinery and piping, etc.

Following documents are checked:

- Perform check of the validity of class certificates (including statutory certificates and class certificates).

- Perform check of ship’s survey records.

- Perform check of the validity of planned maintenance scheme (PMS) for machinery (including the repair/change item in the PMS report made by the chief engineer), if the PMS is applied.

- Perform check of report of lubricating oil analysis record

The documents required for check are also to include an order list or a list of machinery and electrical equipment, specifications of main engine/generating set prime mover, a sea trial report after

delivery, records of repair and maintenance, reports of oil sample analysis, a report of boiler water analysis and a list of spares/tools, etc.

Machinery, electrical installation and cargo related systems scope of the survey:

- Perusal of the maintenance records

- Survey of the system and compartments

- Running tests

- Survey and tests of cargo related system (on tankers)

- Internal survey of selected components

- Measurements of wear down figures

- Survey and tests of the safety systems, automation, and remote control system

- Insulation resistance test

- Oil analysis

- Sea trails

Photographic documentation reflecting the average condition is to be enclosed to the report.

CAP REPORTS

CAP hull report consists of:

- Ship Particulars

- Statement of facts

- General information on CAP ratings

- Course of actions during survey, scope of surveys

- Descriptions and ratings for main structural elements in each tank/space

- Structural strength analysis and required measures to satisfy target rating

- Description and photos of defects,

- Description of repairs and upgrading works,

- Photographic evidence of the condition in each tank/space,

- CAP rating summary

- Analysis of UTM data for each main structural element in each tank/space (enclosure to Report)

MCAP report

The MCAP report at least consists of:

- Ship Particulars

- Statement of facts

- Summary of assessment of machinery and electrical installations

- Record of assessment of machinery and electrical installations

- Photographic evidence of the condition of machinery and electrical installations

- List of machinery and electrical installations

- Sea trial records for main engine/generating set prime mover

- Report for analysis of lubrication oil

- Report for vibration test

- Report for brake tests for windlass and winch as applicable.

CAP CERTIFICATE

A CAP Certificate is issued after completion of the Condition Assessment Program.

The certificate will contain:

- The vessel identification data,

- The place and period of survey,

- A summary assessment of hull/machinery and cargo systems,

- Comments (if any).

The certificate will give no period of validity

Examples for rating calculations (oil tanker)

if a vessel is having IRS class then CAP will be done by IRS only or can be done by any other classification society?