PRINCIPLE OF REFRIGERATION

- Just as the natural flow of water is from a high level to a low level, the natural flow of heat too is from a body at high temperature to a body at a low temperature, and just as we would need a pump to reverse the flow or pump water upwards, we need mechanical work to be done or a heat pump to transfer heat from a body at a low temperature and give it to a body at a high temperature.

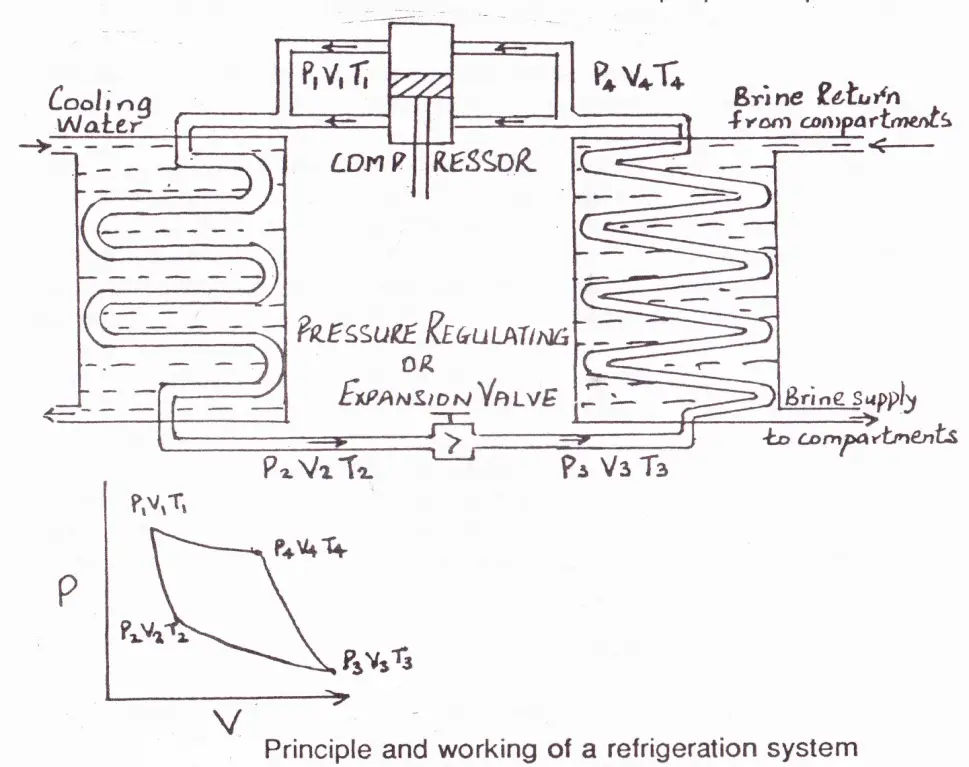

- In a refrigeration system, gas at a high PR. P¹, low vol. V¹ & high temp T¹ (35°C to 40°C) is obtained from the compressor. It is allowed to expand slightly & cool in the condenser to a liquid at pressure P², vol. V² & SW temp T².

- This cooled liquid gas is suddenly allowed to expand by passing through an expansion valve.

- The expansion of the gas to vol. V³ is accompanied by a slight fall in its pressure P³ and a large fall in its temp. to T³(5°C to 25°C).

- The gas is now kept in contact with the substance to be cooled.

- It absorbs heat from the substance and cools it while in turn, its own temp rises to T⁴ (25° to 35°C) and pressure & volume to P⁴ & V⁴

- It is then compressed in a compressor to its pressure, volume & temperature at the first stage, i.e. P¹, V¹ & T¹.

Refrigerated cargoes

Refrigerated cargo is divided into 3 categories:

- Frozen cargoes

- Chilled cargoes

- Cooled cargoes

Frozen cargoes

- eg. Meat, butter, poultry and fish.

- These cargoes are carried in a hard frozen state at temperatures around-8°C to -18°C to prevent the growth of bacteria.

Chilled cargoes

- eg. cheese, eggs, fruits and fresh vegetables.

- Beef may also be carried in a chilled state as the tissues get damaged sometimes by freezing.

- Temperatures maintained around 6°C to -2°C.

- It is more critical to maintain right temperatures of chilled cargoes as condensation of moisture due to the variation of temperature encourages bacterial growth.

Cooled cargoes

- eg. fruits and fresh vegetables.

- Temperatures maintained around 2°C to 13°C by air circulation.

The temperature at which the above cargoes are carried may vary beyond the above-mentioned limits depending on:

- the nature of the cargo,

- the ambient temperature at the load port,

- the duration of the voyage

- and the state in which the cargo is to be delivered (whether ripe, frozen, ready for consumption, etc.

REFRIGERATION SYSTEMS

There are two types of refrigeration systems:

Direct systems

- in small refrigerated chambers on small ships and provision stores on ships.

- in large installations it is difficult to monitor the pipes for leakages, wastage of expensive gas would results. Due to which an indirect system is used on large ships/compartments.

Indirect method and a second refrigerant

- The primary refrigerant is used to cool a tank of brine and this cooled brine is then circulated through the compartment.

- Brine is chosen because of its low freezing point, -20° to -30°C, depending on its concentration and composition.

- The brine is passed through separate grids surrounding the same compartment.

- If one grid is blocked or chocked, the brine supply can be increased to other grids so that cooling will not be affected.

- Cooling is carried out by a combination of cold brine and cool air circulation.

Very good job and will done

Thank you Capt. Saleh.. Really Glad article was helpful to you.

Very good and helpful article………….. please note a correction in the Indirect method and second refrigerant – the freezing point of brine should be -20’c to – 30’c ………………… its a typing error …… (-) sign is missing

Danish, thank you so much for your input. Article update accordingly.

Really appreciate.

I really appreciate the pain taken by the author to gather all information and explain in the most simplest way… Thank you very much for the notes.