There are many types of pumps, each with its own characteristics, advantages and disadvantages. Basically, pumps can be broadly categorised into 3 types :

- Non-positive-displacement pumps e.g. centrifugal pumps

- Positive displacement pumps e.g. reciprocating pumps, gear pumps, screw pumps, etc. Special devices like eductors which can also be included in this category.

Centrifugal Pumps

This type of pump does not have a self-priming capability. Consequently, it operates best only when there is a positive head on the suction side. However, this pump has the distinct capability of having a large throughput. The pump increases the liquid’s velocity by means of a rotating impeller. The pump is normally started with the discharge valve closed. However, keeping the discharge valve closed for a long period tends to heat up the liquid and the pump since the liquid is only churning within. While taking rounds in the pump room it is important to feel the casing to detect any signs of overheating. A sharp eye should also be kept for any signs of leakage through joints and glands.

Vac-strip pump

A centrifugal pump, by itself, is not suitable for emptying a cargo tank since it is not a positive displacement pump. It will then start cavitating when some liquid is still left in the tank and eventually lose suction. For this reason, one often finds a vac-strip system on the ship. This consists of a separator tank in-line with the suction end of the main cargo pump. The vac-strip pump creates a vacuum in the main cargo pump as well as the separator tank which feeds the pump, thus creating an artificial positive cargo head.

The vac-strip pump consists of a rotating impeller which creates a suction and draws out air/gas. A water sealing and cooling system are also provided for the pump.

Reciprocating Pump

These pumps are driven by electric motors or by steam. The prime mover imparts a reciprocating motion to the plunger which moves within the pump cylinder. The pump plunger is sealed against the internal circumference of the liner with the help of ‘o’ rings, bucket rings or piston rings. As the plunger retracts, increase in volume within the cylinder, causes pressure to drop and thus the fluid is pushed into the cylinder via the suction valve (the delivery valve remains closed during this stroke). As the plunger extends it forces the fluid out through the delivery valve (suction valve remains closed during this stroke).

These pumps are positive displacement and deliver their rated flow irrespective of load pressure. Thus it is essential to have a relief valve on the delivery side of the pump. An accumulator (air vessel) is also fitted on the delivery side to dampen the pulsations, which are inherent in this type of pump

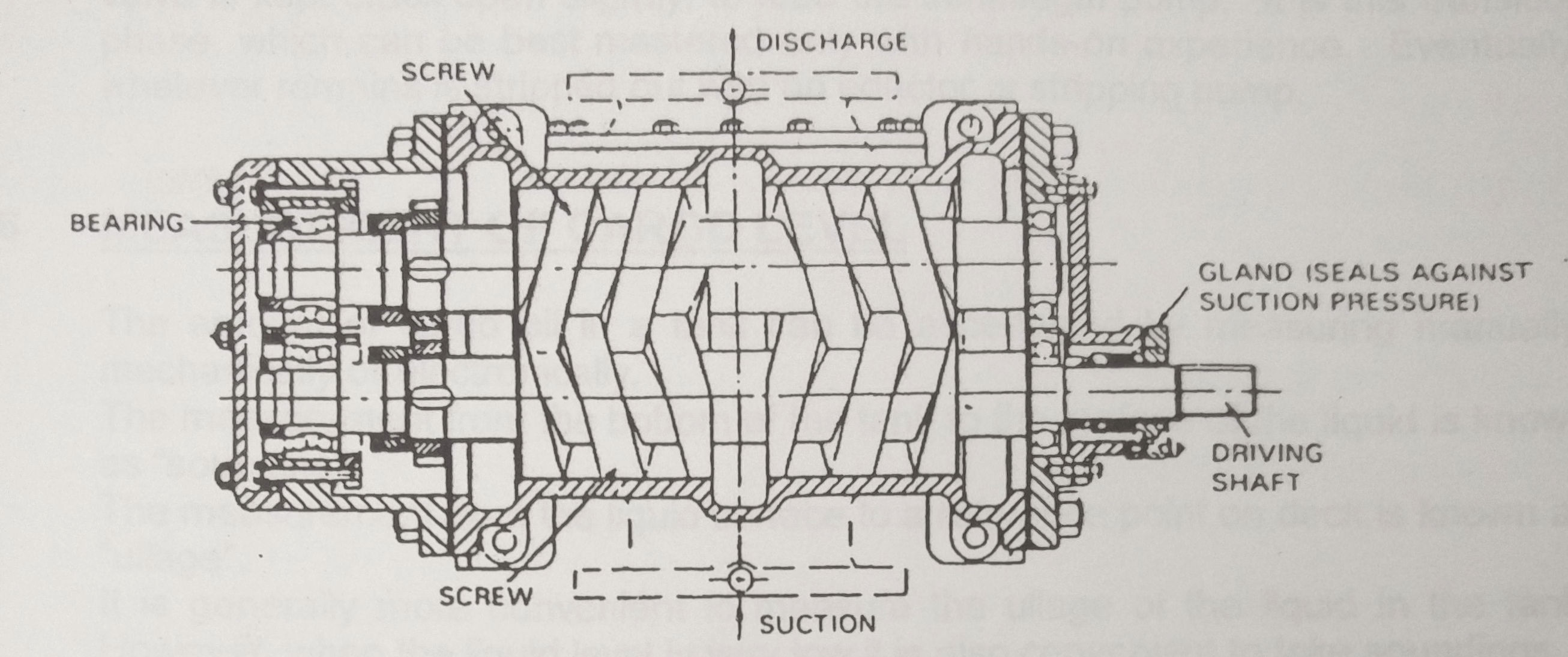

Screw pump

This pump consists of one or more screws (termed screws because of their surface profile). It consists of a central drive screw connected to the prime mover.

The other screw(s) known as idlers are meshed with the central drive screw. As the screws rotate, the liquid is pushed to the discharge side. The pump is self-priming and it does not set up vibrations or pulsations. These pumps are generally used to handle lubricating and other clean oils.

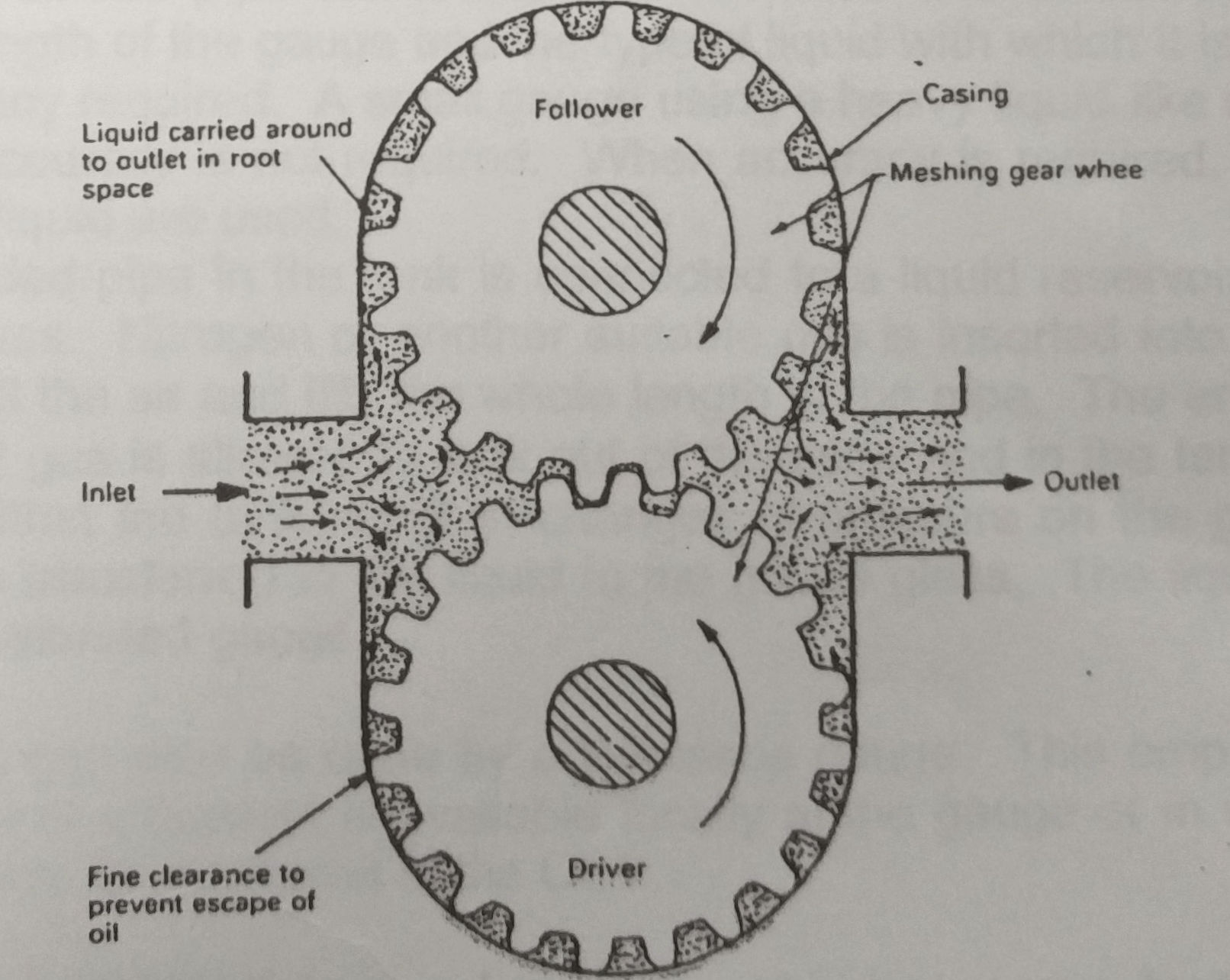

Gear pump

This is a positive displacement pump, which is very similar to a screw pump. It consists of 2 gears, which mesh together within the body. As the gears rotate the liquid is trapped between the casing and the gear teeth. The liquid is forced out to the discharge side.

Eductors/Ejector

An eductor is used for stripping tanks. It has no moving parts and therefore easy to maintain. It operates on Bernoulli’s principle. The driving propellant (fluid from main cargo pump), is forced through the nozzle, thereby creating a vacuum on the suction side. The driving propellant is discharged along with the stripped fluid.

*In fluid dynamics, Bernoulli’s principle states that for an inviscid flow of a non-conducting fluid, an increase in the speed of the fluid occurs simultaneously with a decrease in pressure or a decrease in the fluid’s potential energy.

when i was engine cadetin ship i looked this page for understand what is pump types and how it is work, but i forgot the leave a reply. And now i came for a reason your site again and i remembered i looked this page when i was a cadet. You`re doing great job, great website thanks for everything

Hello Cenk A. Thankyou so much for your kind words, really appreciate a lot.

Well there are different types of pumps available in market as you need to understand your needs according to it moreover to choose best Extractors Pump in Vancouver you need to know its ratings which are provided by customers see customer rating whether they are happy to use it or not.

Do reciprocating (positive displacement) pumps have a relief valve or can they put out infinite pressure ?

Yes, a relief valve is present which relieves additional pressure in an event avoiding damage to the pump.

I appreciate that you explained these positive displacement pumps give their rated flow regardless of load pressure. My best friend is looking for some info, this should help him. I appreciate that you helped me learn more about pumps.