Different Types of Gas Tanker Ships

Gas carriers can be grouped into five different categories according to the cargo carried and the carriage condition. These are as follows:

- Fully pressurised ships

- Semi-pressurised ships

- Ethylene ships

- Fully refrigerated LPG ships

- LNG ships

The first three ship types listed are most suitable for the shipment of smaller-size cargoes of LPG and chemical gases. This is normally accomplished on short-sea and regional routes. Fully refrigerated ships are used extensively for the carriage of large size cargoes of LPG and ammonia on the deep sea routes.

1. Fully pressurised ships

- Fully pressurised ships are the simplest of all gas carriers. They carry their cargoes at ambient temperature.

- They are fitted with Type ‘C’ tanks (pressure vessels) fabricated in carbon steel having a typical design pressure of about 18 barg. Ships with higher design pressures are in service and a few ships can accept cargoes at pressures of up to 20 barg.

- No thermal insulation or reliquefaction plant is necessary for these ships and cargo can be discharged using either pumps or compressors.

- Because of their design pressure, the cargo tanks are extremely heavy. As a result, fully pressurised ships tend to be small having cargo capacities of about 4,000 to 6,000 m3, and are primarily used to carry LPG and ammonia.

- Ballast is carried in double bottoms and in top wing tanks. Because these ships are fitted with Type ‘C’ containment systems, no secondary barrier is required and the hold space may be ventilated with air.

2. Semi-pressurised ships

- Semi-pressurised ships are similar to fully pressurised ships in a context that they have Type ‘C’ tanks — in this case, pressure vessels designed typically for a maximum working pressure of from 5 to 7 barg. Compared to fully pressurised ships, a reduction in tank thickness is possible due to the reduced pressure but this is at the cost of refrigeration plant and tank insulation.

- This type of gas carrier has evolved as the optimum means of transporting a wide variety of gases such as LPG, vinyl chloride, propylene, and butadiene. They are most frequently found in the busy coastal trades around the Mediterranean and Northern Europe. Today, this type of ship is the most popular amongst operators of smaller-size gas carriers due to its cargo handling flexibility.

- Semi-pressurised ships use Type ‘C’ tanks and, therefore, do not require a secondary barrier (cargo capacities can vary from 3,000 to 20,000 m3). The tanks are usually made from low-temperature steels to provide for carriage temperatures of -48°C which temperature is suitable for most LPG and chemical gas cargoes.

- Alternatively, they can be made from special alloyed steels or aluminium to allow for the carriage of ethylene at -104°C (see also ethylene ships). The ship’s flexible cargo handling system is designed to load from (or discharge to) both pressurised and refrigerated storage facilities.

3. Ethylene ships

- Ethylene ships are often built for specific trades but will also operate carrying LPGs or Chemical Gases. They normally have capacities ranging from 1,000 to 12,000 m3.

- Ethylene is normally carried in its fully refrigerated condition at its atmospheric boiling point of – 104°C. Normally Type ‘C’ pressure vessel tanks are used and no secondary barrier is required. Thermal insulation and a high-capacity reliquefaction are fitted on this type of ship.

- Ballast is carried in the double bottom and wing ballast tanks.

- A complete double hull is required for all cargoes carried below -55°C, whether the cargo tanks are of Type ‘A’, ‘B’ or ‘C’.

4. Fully refrigerated ships

Fully refrigerated ships carry their cargoes at approximately atmospheric pressure and are designed to transport large quantities of LPG and ammonia. Four different cargo containment systems have been used for these ships. They are as follows:—

1. Independent tanks with single hull but double bottom and hopper tanks

2. Independent tanks with double hull

3. Integral tanks (incorporating a double hull), and

4. Semi-membrane tanks (incorporating a double hull)

- For this class of ship, the tank itself is a Type ‘A’ prismatic free-standing unit capable of a Maximum working pressure of 0.7 barg. The tanks are constructed of low-temperature steels to permit carriage temperatures of about -48°C.

- Fully refrigerated ships range in size from about 20,000 to 100,000 m3. There are relatively few fully refrigerated ships between 55,000 m3 and 70,000 m3.

- A typical fully refrigerated ship has up to six cargo tanks. Each tank is fitted with transverse wash plates, while a longitudinal bulkhead on the centre line is provided to reduce free surface so improving ship stability. The tanks are usually supported on wooden chocks and are keyed to the hull to allow for expansion and contraction as well as to prevent tank movement under static and dynamic loads. The tanks are also provided with anti-flotation chocks to avoid lifting in case of ballast tank leakage.

- Because of the low-temperature carriage conditions, thermal insulation and reliquefaction equipment must be fitted.

- To improve a fully refrigerated ship’s operational flexibility, cargo heaters and booster pumps are often fitted to allow discharge into pressurised storage facilities. This will normally be accomplished at reduced discharge rates.

- Where Type ‘A’ tanks are fitted, a complete secondary barrier is required

- The hold spaces must be inerted when carrying flammable cargoes.

- Ballast is carried in double bottoms and in top side (saddle) tanks or, when fitted, inside ballast tanks.

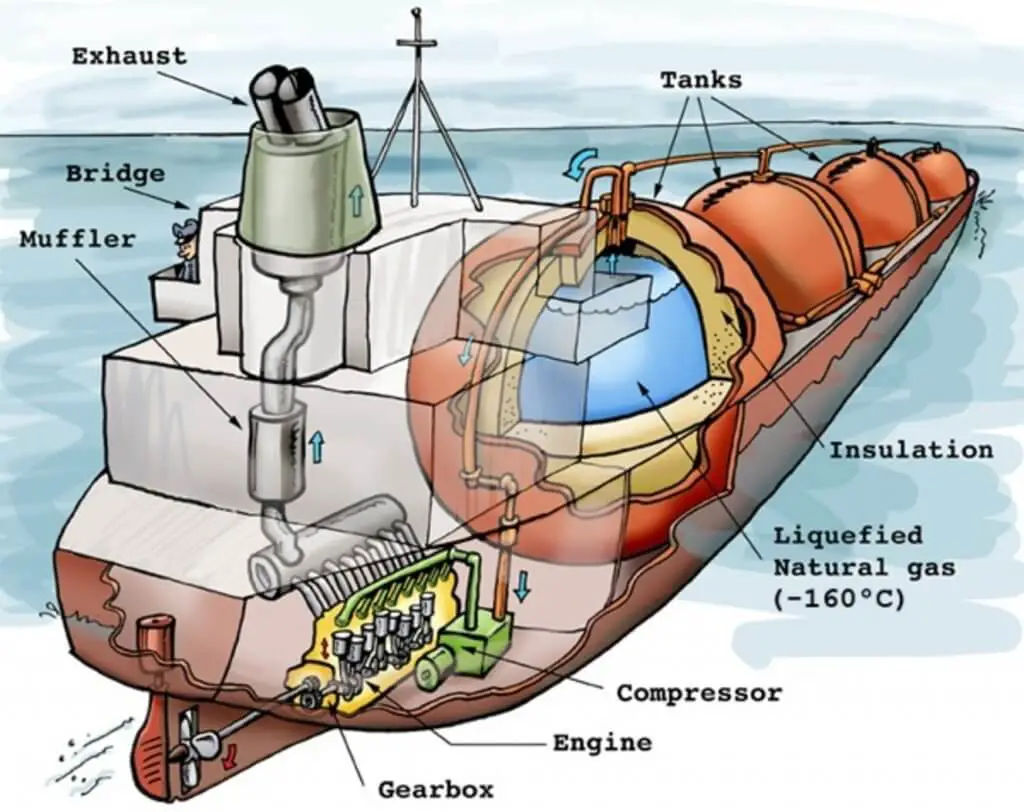

5. LNG ships

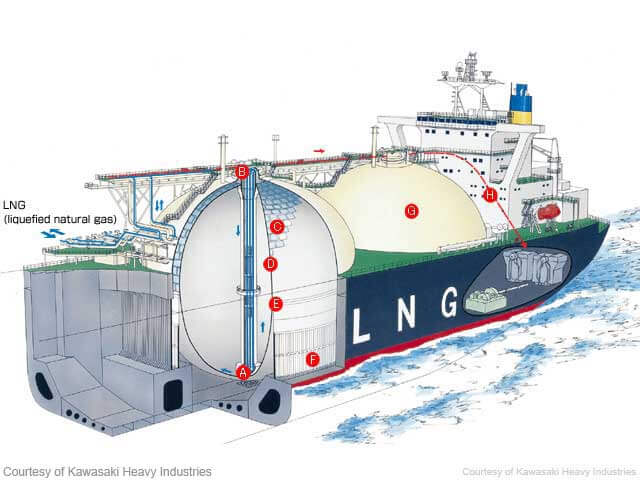

LNG carriers are specialised types of gas carriers built to transport large volumes of LNG at its atmospheric boiling point of about -162° C.

- These ships are now typically of between 125,000 and 135,000 m3 capacity and are normally dedicated to a specific project. Here they often remain for their entire contract life, which may be between 20-25 years or more.

The containment systems on these ships are mainly of four types:

1. Gaz Transport membrane

2. Technigaz membrane

3. Kvaerner Moss spherical — independent Type ‘B’ , and

4. IHI SPB Tank — prismatic

- All LNG ships have double hulls throughout their cargo length which provide adequate space for ballast.

- Ships fitted with the membrane systems have a full secondary barrier and tanks of the Type ‘B’ design have drip-pan type protection.

- A characteristic common to all LNG ships is that they burn cargo boil-off as fuel.

- Hold spaces around the cargo tanks are continuously inerted, except in the case of spherical Type ‘B’ containment where hold spaces may be filled with dry air provided that there is an adequate means for inerting such spaces in the event of cargo leakage.

- Most LNG carriers have steam turbine propulsion plants.

Different Types of Cargo Containment Systems for LNG

CARGO CONTAINMENT SYSTEMS

A cargo containment system is an overall arrangement for containing cargo including, where fitted:

- A primary barrier (the cargo tank),

- Secondary barrier (if fitted),

- Associated thermal insulation,

- Any intervening spaces, and

- Adjacent structure, for the support of these elements.

For cargoes carried at temperatures between -10°C and -55°C the ship’s hull may act as the secondary barrier and in such cases, it may be a boundary of the hold space. The basic cargo tank types utilized on board gas carriers are in accordance with the list below:

Independent tanks

Independent tanks are completely self-supporting and do not form part of the ship’s hull structure. Moreover, they do not contribute to the hull strength of a ship. As defined in the IGC Code, and depending mainly on the design pressure, there are three different types of independent tanks for gas carriers: these are known as Types ‘A’, ‘B’ and ‘C’.

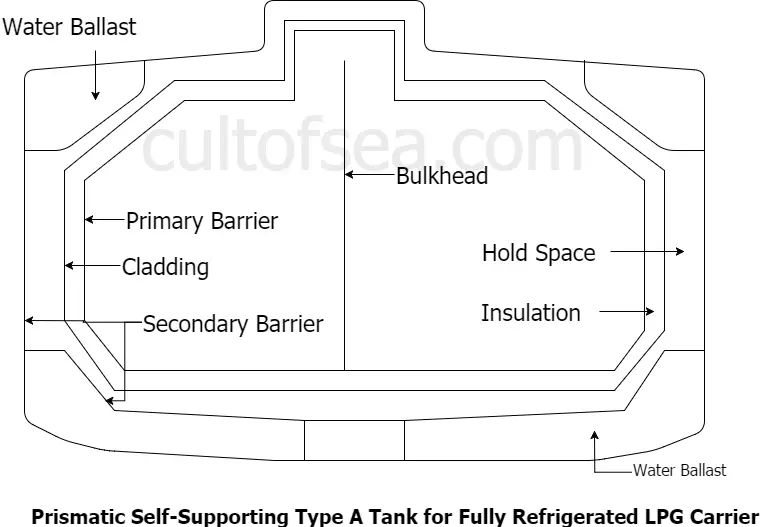

Type ‘A’ tanks

Type ‘A’ tanks are constructed primarily of flat surfaces. The maximum allowable tank design pressure in the vapour space for this type of system is 0.7 barg; this means cargoes must be carried in a fully refrigerated condition at or near atmospheric pressure (normally below 0.25 barg).

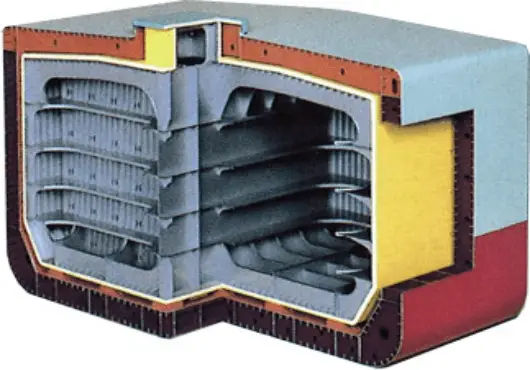

Figure below shows a section through this type of tank as found on a fully refrigerated LPG carrier. This is a self-supporting prismatic tank which requires conventional internal stiffening. In this example the tank is surrounded by a skin of foam insulation. Where perlite insulation is used, it would be found filling the whole of the hold space.

The material used for Type ‘A’ tanks is not crack propagation resistant. Therefore, in order to ensure safety, in the unlikely event of cargo tank leakage, a secondary containment system is required. This secondary containment system is known as a secondary barrier and is a feature of all ships with Type ‘A’ tanks capable of carrying cargoes below -10°C.

For a fully refrigerated LPG carrier (which will not carry cargoes below -55°C) the secondary barrier must be a complete barrier capable of containing the whole tank volume at a defined angle of heel and may form part of the ship’s hull, as shown in the figure. By this means appropriate parts of the ship’s hull are constructed of special steel capable of withstanding low temperatures. The alternative is to build a separate secondary barrier around each cargo tank. The IGC Code stipulates that a secondary barrier must be able to contain tank leakage for a period of 15 days.

On such ships, the space between the cargo tank (sometimes referred to as the primary barrier) and the secondary barrier is known as the hold space. When flammable cargoes are being carried, these spaces must be filled with inert gas to prevent a flammable atmosphere being created in the event of primary barrier leakage.

Type ‘B’ tanks

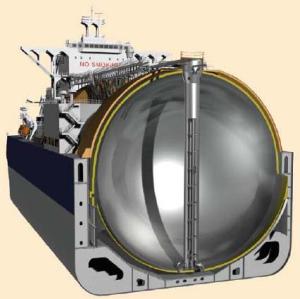

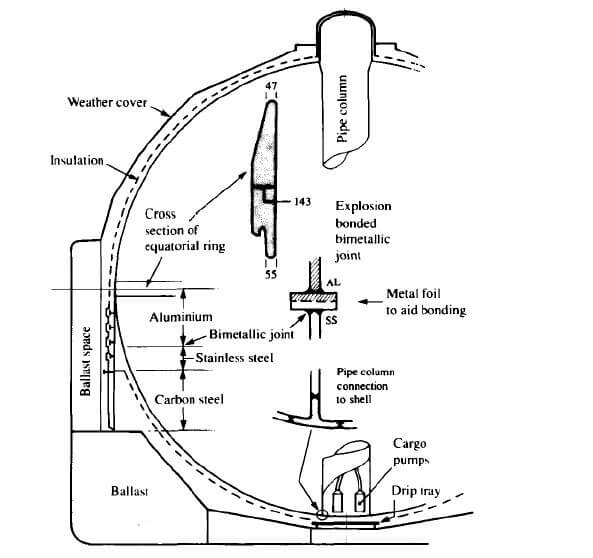

Type ‘B’ tanks can be constructed of flat surfaces or they may be of the spherical type. This type of containment system is the subject of much more detailed stress analysis compared to Type ‘A systems. These controls must include an investigation of fatigue life and a crack propagation analysis. These tanks may be able to withstand pressures up to 2 barg. The most common arrangement of Type ‘B’ tank is a spherical tank as illustrated in Figure 3.2. This tank is of the Kvaerner Moss design. Because of the enhanced design factors, a Type ‘B’ tank requires only a partial secondary barrier in the form of a drip tray. The hold space in this design is normally filled with dry inert gas. However, when adopting modern practice, it may be filled with dry air provided that inerting of the space can be achieved if the vapour detection system shows cargo leakage. A protective steel dome covers the primary barrier above deck level and insulation is applied to the outside of the tank. The Type ‘B’ spherical tank is almost exclusively applied to LNG ships; seldom featuring in the LPG trade.

A Type ‘B’ tank, however, need not be spherical. There are Type ‘B’ tanks of prismatic shape in LNG service. The prismatic Type ‘B’ tank has the benefit of maximising ship hull volumetric efficiency and having the entire cargo tank placed beneath the main deck. Where the prismatic shape is used, the maximum design vapour space pressure is, as for Type ‘A tanks, limited to 0.7 barg.

Cross Section View of Type B Tank Ship

Type B Tank being installed into ships hold

Spherical Tank IMO Type B

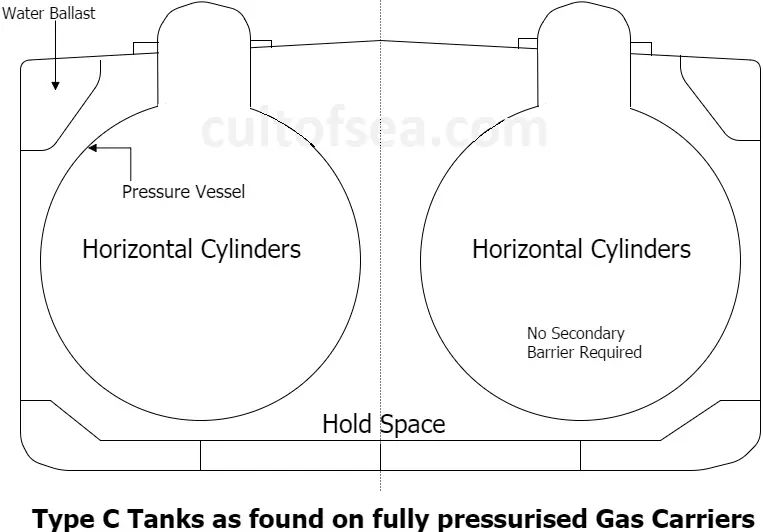

Type ‘C’ tanks

Type ‘C’ tanks are normally spherical or cylindrical pressure vessels having design pressures higher than 2 barg. The cylindrical vessels may be vertically or horizontally mounted.

This type of containment system is always used for semi-pressurised and fully pressurised gas carriers. Type ‘C’ tanks are designed and built to conventional pressure vessel codes and, as a result, can be subjected to accurate stress analysis. Furthermore, design stresses are kept low. Accordingly, no secondary barrier is required for Type ‘C’ tanks and the hold space can be filled with either inert gas or dry air.

In the case of a typical fully pressurised ship (where the cargo is carried at ambient temperature), the tanks may be designed for a maximum working pressure of about 18 barg. For a semi-pressurised ship the cargo tanks and associated equipment are designed for a working pressure of approximately 5 to 7 barg and a vacuum of 0.5 barg. Typically, the tank steels for the semi-pressurised ships are capable of withstanding carriage temperatures of -48°C for LPG or -104°C for ethylene. (Of course, an ethylene carrier may also be used to transport LPG.)

Figure below shows Type ‘C’ tanks as fitted in a typical fully pressurised gas carrier. With such an arrangement there is comparatively poor utilisation of the hull volume; however, this can be improved by using intersecting pressure vessels or bi-lobe type tanks which may be designed with a taper at the forward end of the ship.

A Type C Tank being installed.

A ship under construction in shipyard with IMO Type C Tanks

Membrane tanks (membrane – 0.7 to 1.5 mm thick)

The concept of the membrane containment system is based on a very thin primary barrier (membrane – 0.7 to 1.5 mm thick) which is supported through the insulation. Such tanks are not self-supporting like the independent tank & an inner hull forms the load-bearing structure. Membrane containment systems must always be provided with a secondary barrier to ensure the integrity of the total system in the event of primary barrier leakage. The membrane is designed in such a way that thermal expansion or contraction is compensated without over-stressing the membrane itself.

There are two principal types of membrane system in common use

- Gaz Transport membrane system

- Technigaz membrane system

Both named after the companies who developed them and both designed primarily for the carriage of LNG.

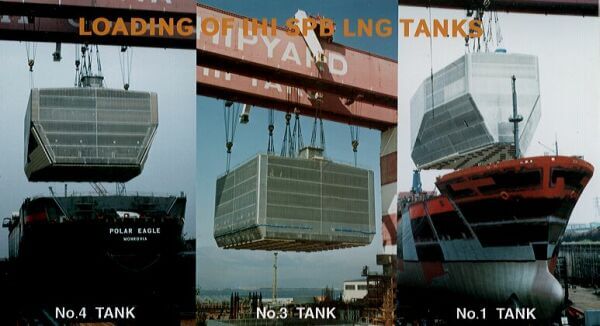

Initially, the Moss system was more popular, but higher Suez toll fees due to their higher gross tonnage made Moss vessels less attractive for trades involving the Suez Canal. Recently Moss has staged a comeback and currently, there are about 30 Moss vessels on order against 100+ membrane vessels. A fourth LNG containment system joined the ranks of the large marine LNG cargo tank designs in the early 1990’s; the Japanese IHI SPB (Self-supporting Prismatic shape IMO type-B) system. With only two orders for LNG carriers in the 1990’s, this system seemed to be inaccessible due to its high price. However, in 2014 four vessels were ordered with the SPB system, bringing it back as a credible alternative to the membrane systems and the Moss system.

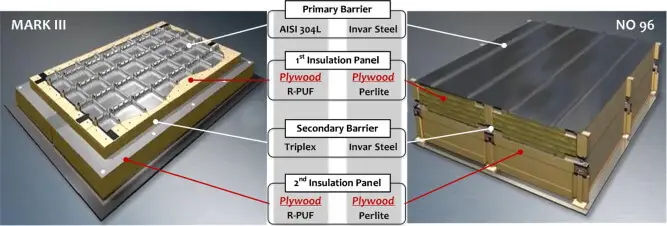

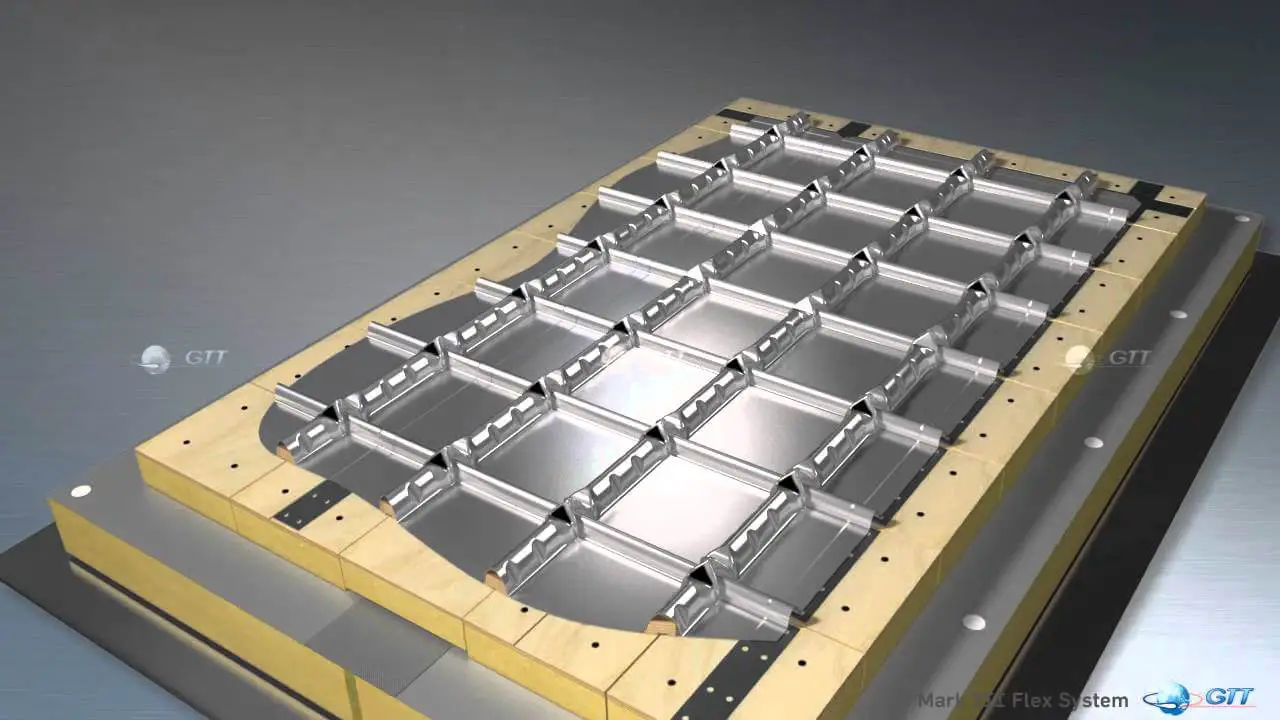

Membrane systems

Technigaz designed a membrane type atmospheric LNG containment system with a corrugated stainless steel primary membrane supported by wooden boxes filled with insulation material. A secondary cryogenic barrier, also supported by wooden boxes filled with insulation material provides containment of the cryogenic cargo in case the primary membrane develops a leak. The characteristic corrugations in the primary membrane allow for the shrinkage of metal under cryogenic temperatures. This design, identified as the Mk I was soon superseded by improved versions and is currently available as the Mk III series from a number of shipyards in Korea and Japan. Soon the Mk V series will be going into production, which replaces the current Triplex secondary barrier with a corrugated stainless steel secondary barrier.

Compatriot Gaztransport designed a rather similar system consisting of a primary membrane supported by insulation in plywood boxes and a secondary membrane, also supported by insulation in plywood boxes. This system was called the No 88 system and featured a primary and secondary membrane of a steel alloy with a negligible contraction coefficient. Improvements have been over the years and the current system is the No 96, which is being used in LNG carriers under construction in Korea and China.

After years of competition, Gaztransport and Technigaz merged to form GTT, which has been developing and promoting both membrane type containment systems in parallel. GTT has licensed these systems to all major LNG carrier builders around the world. The main advantage of the membrane type containment systems is their prismatic shape, which allows these systems to use the space available within the hull of the LNG carrier to a very high degree. With the cargo tanks recessed deep inside the hull under a low trunk deck, membrane type LNG carriers do not need a high deck house to have good visibility. This results in the typical “squat” silhouette of this type of vessels. In France, GTT proposed membrane type LNG fuel tanks for the proposed newbuilding ferry for Brittany Ferries. Unfortunately this project was put on hold for the time being for non-technical reasons.

Both membrane systems have one traditional weakness; their vulnerability for sloshing damage. Sloshing is the motion of the LNG cargo in the tanks as a result of the motion of the vessel due to the effect of waves and wind. In certain circumstances, waves occur in the LNG cargo which upon impact on the tank walls can cause damage to the primary barrier and the boxes supporting the primary membrane. To counter the risk of sloshing damage, GTT advises the operators of membrane ships to operate their ships with tank levels of more than 90% or less than 10%. For applications that require part load operations, such as LNG Floating Storage and Regas Units (LNG FSRU), membrane systems with specially reinforced boxes have been developed.

Gaztransport Designed Membrane Tank featured a primary and secondary membrane of a steel alloy with a negligible contraction coefficient.

GTT-technology membrane tank model fabricated by Conrad Shipyard.

Cross Section of a Technigaz showing each layer

Technigaz designed a membrane type LNG containment system with a corrugated stainless steel primary membrane supported by wooden boxes filled with insulation material.

https://www.youtube.com/watch?v=t0Td-IvnzlI#t=572.96

For More Info chcek these links given below:

http://www.gtt.fr/en/technologies-services/our-technologies/mark-iii

http://www.gtt.fr/en/technologies-services/our-technologies/mark-v-system

http://www.gtt.fr/en/technologies-services/our-technologies/no96

The Moss system

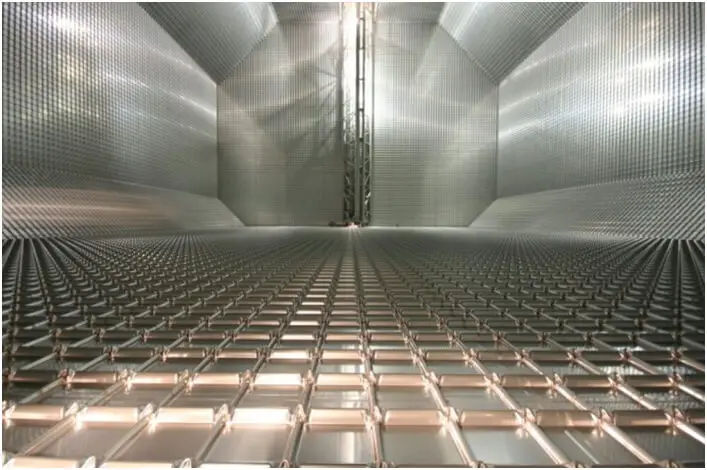

The Moss spherical LNG containment system does not have these sloshing issues. Its aluminium spheres have sufficient structural strength to withstand LNG wave impact due to the interaction between the cargo and the ship’s motion. The Moss system doesn’t need a full secondary barrier like the membrane system; there is only a small drip tray below the spheres to catch any liquid leaking. The design philosophy behind the Moss system is that the tank should be designed to be strong enough so that cracks should not develop in the tanks over the lifetime of the vessel. The structural strength of the containment system is exactly the reason why old Moss vessels are very popular candidates for conversion to LNG FSRU’s or even floating LNG production plants.

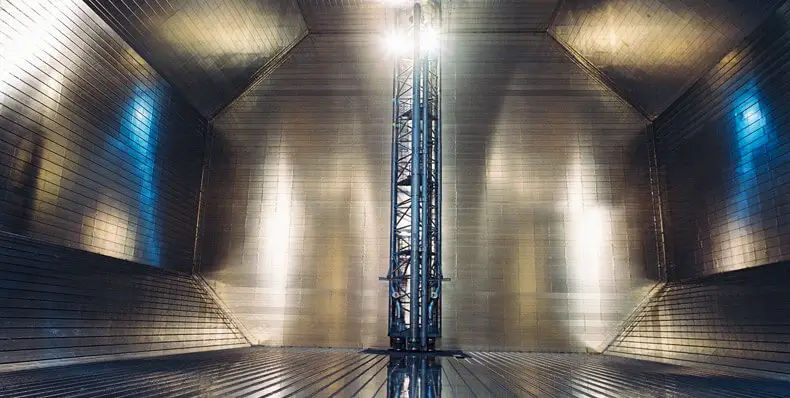

View from inside of Tank

View from inside the hold of ship

The only true disadvantage of the Moss vessels is the fact that the containment system has a very low hull space utilization rate. The sheers are mounted on the deck of the vessel by way of an equatorial ring, which means that half the sphere protrudes above the deck. While this makes for the characteristic silhouette of the Moss carrier, it also necessitates a high deck house to ensure adequate line of sight from the bridge. The low hull space utilization means that a Moss carrier has a higher GT rating than membrane carriers of similar cargo capacity, which translates in higher port and fairway dues and higher tonnage taxes.

The SPB system

The fourth LNG cargo containment system, the IHI (now JMU) SPB system manages to combine the advantages of the membrane system and the Moss system and addresses the disadvantages of both systems too. The prismatic shape of the tanks ensures a high hold space utilization rate and a low air draft, while the solid aluminum construction with a centerline bulkhead and transverse swash bulkheads reduces liquid motion in the tanks and minimizes the risk for sloshing damage, even in part load conditions. The high price of this system originally prevented wide spread adoption but in 2014 JMU, the successor to SPB designer IHI, secured orders for tanks for four 165,000 m3 LNG carriers and it has been addressing the only true disadvantage of this system; its price tag. With possible licensing overseas, the SPB system could become a very serious contender in the LNG containment system arena. In Japan, JMU has already carried out a study with a shipyard into the feasibility of SPB tanks as LNG fuel tanks.

SPB Tank being installed into Ships Hold

A SPB Tank designed by IHI Japan

“IHI-SPB” (Self-supporting, Prismatic Shape, IMO type B) is Japanese own technology developed by IHI Group while the competing technologies used for LNG floaters including LNG carriers by Japanese and Korean shipyards are imported from Europe (Norwegian Moss technology and French Membrane technology). “IHI-SPB” has unique features of “No Sloshing” which enables any level loading of LNG inside the tank at offshore, “Flat upper deck” which enables installation of the topside plants on upper deck, “Less and Easy Maintenance”, etc. and is most suited to use in the LNG floaters including FLNG and FSRU required to stay offshore and operate safely for long years without dry docking.

MT Polar Eagle With SPB Tanks

Integral tanks

Integral tanks form a structural part of the ship’s hull and are influenced by the same loads which stress the hull structure. Integral tanks are not normally allowed for the carriage of liquefied gas if the cargo temperature is below -10°C. Certain tanks on a limited number of Japanese-built LPG carriers are of the integral type for the dedicated carriage of fully refrigerated butane.

Internal insulation tanks

Internally insulated cargo tanks are similar to integral tanks. They utilise insulation materials to contain the cargo. The insulation is fixed inside ship’s inner hull or to an independent load-bearing surface. The non-self-supporting system obviates the need for an independent tank and permits the carriage of fully refrigerated cargoes at carriage temperatures as low as -55°C. Internal insulation systems have been incorporated in a very limited number of fully refrigerated LPG carriers but, to date, the concept has not proved satisfactory in service.

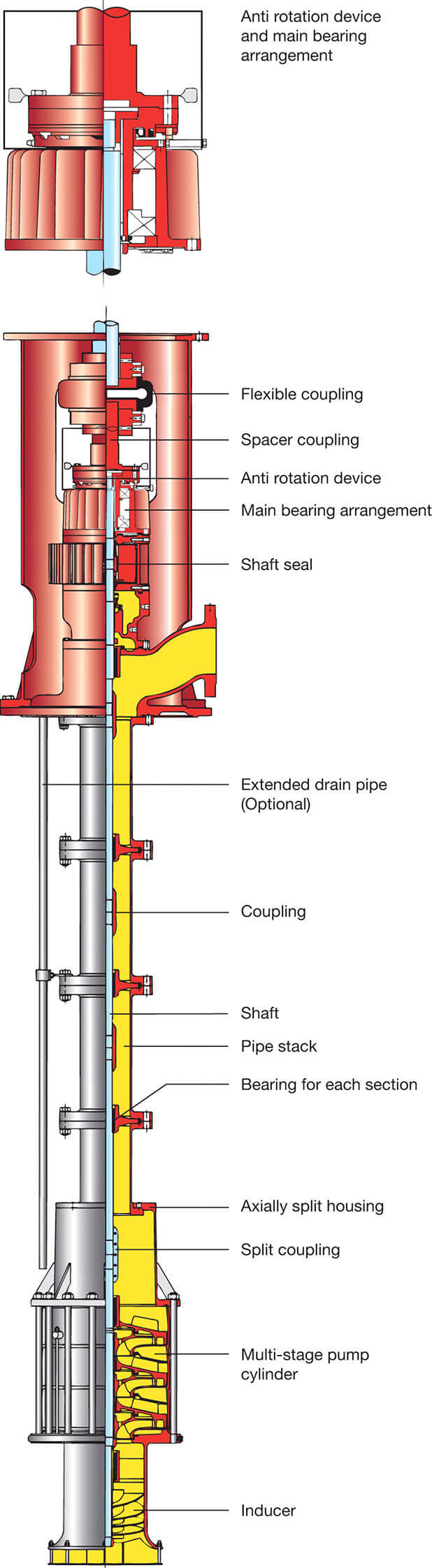

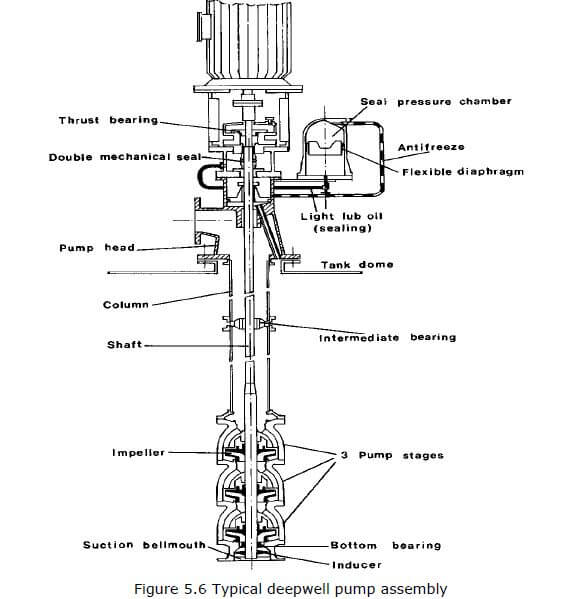

Deep Well Cargo Pump | High Level alarm and automatic shut-down systems With the exception of Type ‘C’ tanks having a capacity of less than 200 cubic metres, every cargo tank must be fitted with an independent high level sensor giving audible and visual alarms. The float, capacitance or ultrasonic sensors (as covered in 4.9.1) may be used for this purpose. The high-level alarm — or other independent sensor — is required to automatically stop the flow of cargo to the tank. During cargo loading, there is a danger of generating a significant surge pressure if the valve stopping the flow closes too quickly against a high loading rate.

|

RELIQUEFACTION PLANTS AND BOIL-OFF CONTROL

With the exception of fully pressurised gas carriers, means must be provided to control cargo vapour pressure in cargo tanks during cargo loading and on passage. In the case of LPG and chemical gas carriers, a reliquefaction plant is fitted for this purpose. This equipment is designed to perform the following essential functions:

- To cool down the cargo tanks and associated pipelines before loading;

- To reliquefy the cargo vapour generated by flash evaporation, liquid displacement and boiloff during loading; and

- To maintain cargo temperature and pressure within prescribed limits while at sea by reliquefying the boil-off vapour.

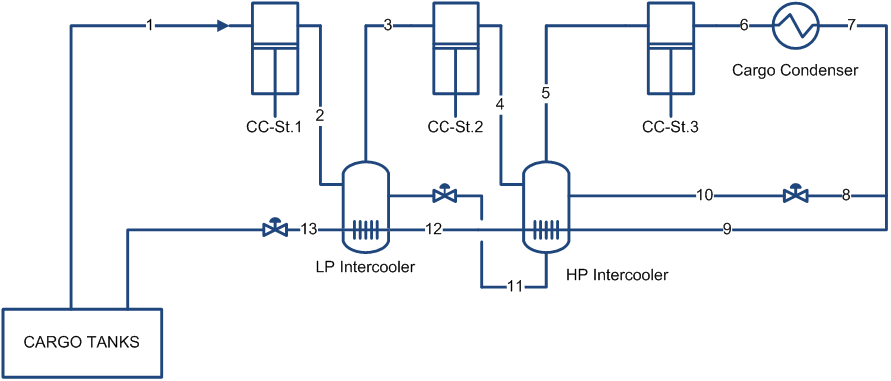

Fully Refrigerated LPG ship’s Re-liquefaction Plant

Assuming a gas carrier comes directly from a shipbuilder or drydock, the general sequence of cargo handling operations is as follows:

TANK INSPECTION -> DRYING -> INERTING -> GASSING UP -> COOL DOWN -> LOADING -> DISCHARGE

Preparation for loading

Tank inspection

Before any cargo operations are carried out it is essential that cargo tanks are thoroughly inspected for cleanliness; that all loose objects are removed; and that all fittings are properly secured. In addition, any free water must be removed. Once this inspection has been completed, the cargo tank should be securely closed and air drying operations may start.

Drying

Drying the cargo handling system in any refrigerated ship is a necessary precursor to loading. This means that water vapour and free water must all be removed from the system. If this is not done, the residual moisture can cause problems with icing and hydrate formation within the cargo system.

Tank atmosphere drying can be accomplished in several ways. These are described below.

- Drying using inert gas from the shore

- Drying using inert gas from ship’s plant

- On board air-drying systems

Inerting — before loading

Inerting cargo tanks, cargo machinery and pipelines is undertaken primarily to ensure a nonflammable condition during subsequent gassing-up with cargo. For this purpose, oxygen concentration must be reduced from 21 percent to a maximum of five percent by volume.

Gassing-Up

Neither nitrogen nor carbon dioxide, the main constituents of inert gas, can be condensed by a ship’s Reliquefaction plant. This is because, at cargo temperatures, each is above its critical temperature and is, therefore, incondensable. Accordingly, removal of inert gas from the cargo tank is necessary. This is achieved by gassing-up, using vapour from the cargo to be loaded at ambient temperature and venting the incondensable to atmosphere so that subsequently the Reliquefaction plant can operate efficiently.

Cool Down

Cooling down is necessary to avoid excessive tank pressures (due to flash evaporation) during bulk loading. Cool-down consists of spraying cargo liquid into a tank at a slow rate. The lower the cargo carriage temperature, the more important the cool down procedure becomes. Before loading a refrigerated cargo, ship’s tanks must be cooled down slowly in order to minimise thermal stresses. The rate at which a cargo tank can be cooled, without creating high thermal stress, depends on the design of the containment system and is typically 10°C per hour. Reference should always be made to the ship’s operating manual to determine the allowable cool-down rate.

Cargo liquid from shore (or from deck storage) is gradually introduced into the tanks either through spray lines, if fitted for this purpose, or via the cargo loading lines. The vapours produced by rapid evaporation may be taken ashore or handled in the ship’s reliquefaction plant. Additional liquid is then introduced at a rate depending upon tank pressures and temperatures.

Cool-down should continue until boil-off eases and liquid begins to form in the bottom of the cargo tanks. This can be seen from temperature sensors Throughout the cool down, deepwell pump shafts should be turned frequently by hand to prevent the pumps from freezing up. Once the cargo tanks have been cooled down, cargo pipelines and equipment should be cooled down.

Loading — Preliminary procedures

Before loading operations begin, the pre-operational ship/shore procedures must be thoroughly discussed and carried out. Appropriate information exchange is required and the relevant parts of the Ship/Shore Safety Check List should be completed.

Particular attention should be paid to:

- The setting of cargo tank relief valves and high alarm pressures

- Remotely operated valves

- Reliquefaction equipment

- Gas detection systems

- Alarms and controls, and

- The maximum loading rate.

The terminal should provide the necessary information on the cargo, including inhibitor certificates where inhibited cargoes are loaded. Any other special precautions for specific cargoes should be made known to ship personnel. The ballast system for gas carriers is totally independent of the cargo system, deballasting can, therefore, take place simultaneously with loading, subject to local regulations. Ship stability and stress are of primary importance during loading

Trim, stability and stress

The cargo plan should allow for distribution within the ship in order to achieve acceptable structural stress and the required ship trim to meet safe stability conditions when at sea.

Sloshing

A further point to be noted in respect of tank filling levels is that, large prismatic cargo tanks, due to their width and shape, may suffer from substantial sloshing of cargo in heavy pitching or rolling conditions. Such tanks, and particularly membrane-type tanks which have no centre line wash bulkheads, may have prohibited filling levels in order to avoid damage to tank structures or internal fittings. Typical controls on such tanks are a prohibition on all filling levels in the 10 to 80 per cent range.

LNG as a fuel

LNG carriers have long been using the boil-off gas from their cargo tanks as fuel for their engines. In 2000, the Norwegian passenger ferry Glutra became the first non-LNG carrier to use LNG as fuel. LNG is a clean burning fuel, consisting of mostly methane and it allows the vessels to comply with upcoming, stricter marine emissions legislation. Regular marine diesel engines operating on residual marine fuels would require exhaust gas after treatment in order to comply with the new emission standards. Dual fuel diesel engines emit hardly any SOx, as there is no sulphur in LNG. Furthermore, they have lower NOx emissions due to their combustion process and in addition the CO2 emissions are lower than those of the regular diesel engines too.

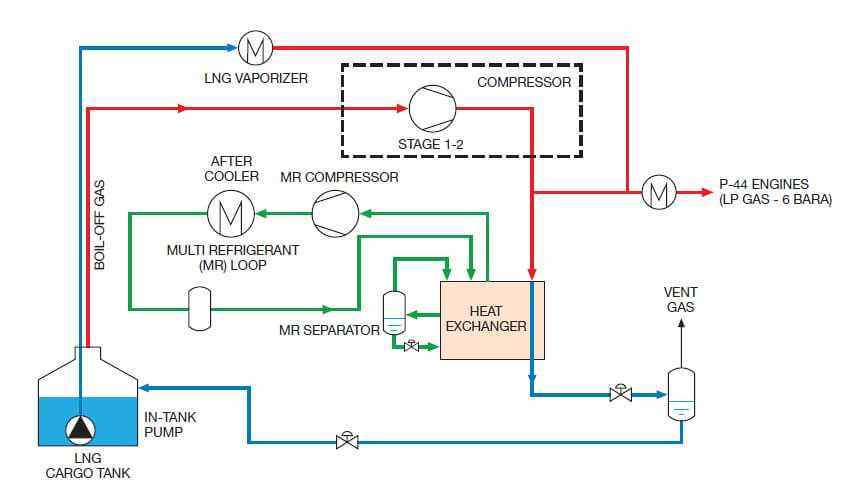

Figure Describing Use of LNG Cargo Vapours as a Fuel

Use of Cargo as fuel

Boil-off from LNG cargo may be burnt as fuel in the main propulsion system. Two factors influence the sanctioning of this practice:

(1) LNG vapour, being mainly methane, is lighter than air at ambient temperatures. It is therefore safe to be used because if it were to leak into the machinery space it would escape through exhaust vents and not accumulate within the machinery space. Consequently, LNG is the only cargo vapour allowed to be used as fuel.

(2) It is possible to burn LNG vapour in boilers, diesel engines or gas turbines. In each case cargo vapour is introduced into a space from which it is normally excluded, and the design of the cargo vapour-to-fuel system is therefore subject to strict requirements. It is vital to ensure that the integrity of the system is not impaired in any way.

LNG boil-off may be either vented or burnt (or both) to keep tank pressures at the required level. The decision whether to vent or burn the boil-off depends on many factors, some economic, some the result of regulations. Regulations may, for instance, either prohibit venting or the use of cargo as fuel in certain places. Such regulations should always be observed.

Note: Attention should also be paid to Chapter 16 of the IGC Code, Regulation II-2/15.1 of the SOLAS Convention, IMO recommendations concerning the use of low flashpoint cargoes as fuel e.g. IMO Resolution A565(14), and to classification requirements.

On the high sea, cargo vapour may provide the main fuel, though oil pilot burners are also required. In the case of steam plants, cargo vapour may also be burnt when propulsion machinery is not in operation provided that means for steam-dumping are installed.

Image courtesy of Respective owners. Images displayed are only for Educational Purposes. However, if owners find it infringing certain exclusive rights, please contact us.

It should mean write my papers that more schools could participate, which is a good persuasive essay writing service thing, he said.

very helpful article ….. thank u so much

Thank you Danish. Really glad that it was helpful.

Well explained

We are trader ex Container and ISO Tank at Jakarta Indonesia. Thanks for explain it

Hello Randhawa!

Just as a friendly comment: There’s a serious error in your description of membrane tanks. The pictures with text “Prismatic membrane tanks being installed in ship’s hold” is nonsense – sorry. Membrane tanks cannot be ‘lifted’ in any sense as the membrane type tanks are actually insulation systems that are assembled piece-by-piece against ship’s flat inner hull and comprise of various types of insulation materials and elements that are finally covered with tight metallic ‘membrane’ (in fact the systems comprise two tight layers but in all membrane systems the inner one is metallic but thin which gives the expression ‘membrane’). The erratic picture (that you should remove from your LNG-ship related article) is showing a ready-built prismatic LPG tanks of cold resistant steel and which have been laid [sprayed] with polyurethane insulation foam. You may notice the [wooden] blocks below the tank that are typical for such semi-refrigerated LPG tanks. The subject tank type and its supporting method has been model for the later “SPB”-tanks intended for LNG. Their tank materials are different (from those of LPG tanks) and also their insulation system is more complex due to very high thermal contraction caused by very low temperature LNG cargo and due to certain ‘small-leak-detection matters’. If you wish, I can send you some own photos where building of a membrane tank, or better: multi-layer membrane insulation panels are being installed on ships inner steel hull.

Another note, also related to membrane tanks: After the picture of “Mark III” membrane system there are two almost similar graphs about the various layers of [Mark III] membrane system. The lowest material refers to “concrete” which is not there if a ship application is in question. The concrete base may exist in shore-based storage tanks that can also be constructed with similar type of “Mark III” type membrane system. layers as pictured . Please go to the license company GTT’s webpage to find a graph of a ship application!

Regarding Moss-type ships I have a wide collection of fine pictures from various stages of the building process of Moss ships and their tanks.

B. R. Mauri Lindholm,

Senior naval architect (with some experience from designing of gas ships & building process of LNG carriers, Finland)

Hello Mauri Lindholm!

First of all Thanks a lot for correcting mistakes in above article. It is very important for us to share the correct information to seafarers. I will be more than happy to get correct pictures/feedback from an Experienced person like you. If you can email those pics to me on capt.randhawa@gmail.com , I will happily edit the article.

Thanks

G.S Randhawa

very well explained……..keep educating the world …all d best

Thank you Vipul. ?

Wow such a nice information, thanks a lot even a non tanker person can understand it

Thankyou Pradeep. Really glad to know that it helped you. Happy Reading!

Extremely educative and nicely narrated.

With best of regards.

This is a very informational article. Many thanks to Cultofsea!

Just wondering what is meaning of NO as in Gaztransport NO96 system. Does it stand for Number or is it an acronym for two single words?

Best regards

Xiao-Ming XU

NICE INFORMATION PROVIDED TO MARINERS. THANKS.

A couple of points.

In your diagram of LNG as fuel, you indicate a compressor in the engine room. This is never the case, the gas compressor is always sited outside of the engine room in the compressor house. Depending on whether the vessel has diesel engines that require high pressure gas supply (300bar) or if the vessel has engines that require fuel gas at a lower pressure around 15 bar or 1 bar the compressors may be reciprocating in the case of 300 bar or reciprocating or multistage centrifugal for 15 bar. 1 bar is generally supplied by a single stage centrifugal compressor for steam ships.

All gas fuel lines entering the engine room are double waled with a air flow surrounding the pipe led to an exhaust riser on deck. If any leakage occurs it is ducted to the riser safely out of the engine room. gas detectors in the duct monitor for the presence of gas and alarm and trip the gas supply to the boiler in the event of leakage.

On fuel gas systems there is always an isolating valve on deck after the compressor and before entering the engine room.

You did not address methane slip. Unburnt methane may pass through the gas burning diesel engine and be ejected through the funnel into the air.. Methane is considerable worse for global warming and ozone depletion than carbon dioxide. Modern diesel engines are addressing this issue, but the best methane slip performance (ie the lowest) is with high pressure LNG burning engines such as the 2 stroke ME-GI engines. next besty is the WinGD 2 stroke engines and medium speed 4 strokes are the worst performers wrt methane slip.

Improvements in diesel engine design are reducing the methane slip levels, and there are now some aftermarket funnel filters being developed to further reduce the methane emissions.