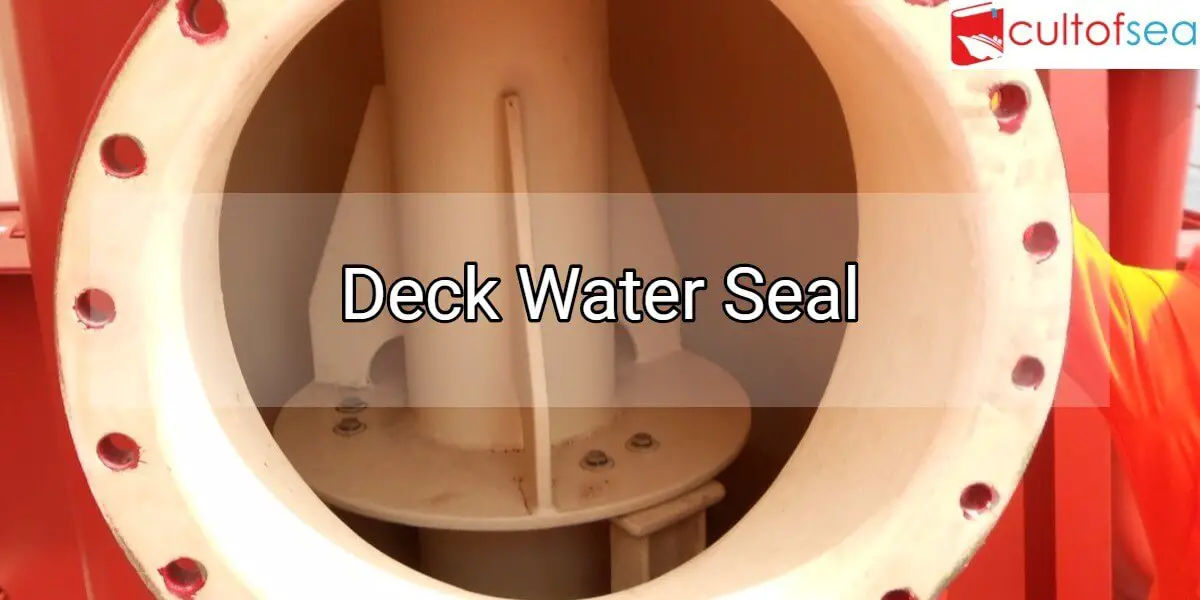

Deck Water Seal

In an inert gas system onboard Tanker ships, Deck water seal is the principal barrier.

A water seal is fitted which permits inert gas to be delivered to the deck main but prevents any backflow of cargo gas even when the inert gas plant is shut down.

It is vital that a supply of water is maintained to the seal at all times, particularly when the inert gas plant is shut down. In addition, drains should be led directly overboard and should not pass through the machinery spaces.

There are different designs but one of three principal types may be adopted:

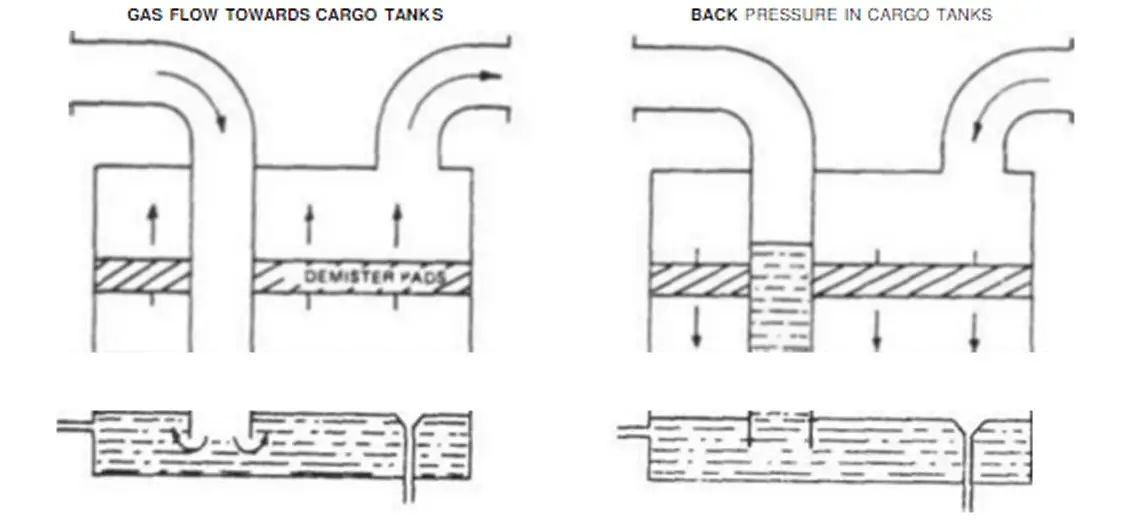

Wet type

This is the simplest type of water seal. When the inert gas plant is operating, the gas bubbles through the water from the submerged inert gas inlet pipe, but if the tank pressure exceeds the pressure in the inert gas inlet line the water is pressed up into this inlet pipe and thus prevents backflow. The drawback of this type of water seal is that water droplets may be carried over with the inert gas which, although it docs not impair the quality of the inert gas, could increase corrosion. A demister should, therefore, be fitted in tlie gas outlet from the water seal to reduce any carry-over.

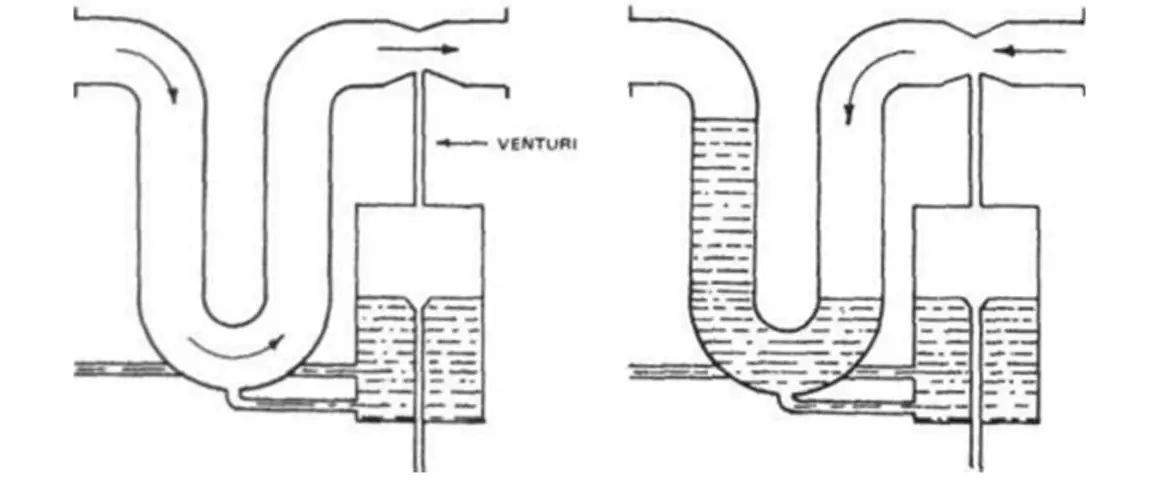

Semi-dry type

Instead of bubbling through the water trap the inert gas flow draws the sealing water into a separate holding chamber by venturi action thus avoiding or at least reducing the amount of water droplets being carried over. Otherwise it is functionally the same as wet type.

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section of pipe. The Venturi effect is named after Giovanni Battista Venturi (1746–1822), an Italian physicist.

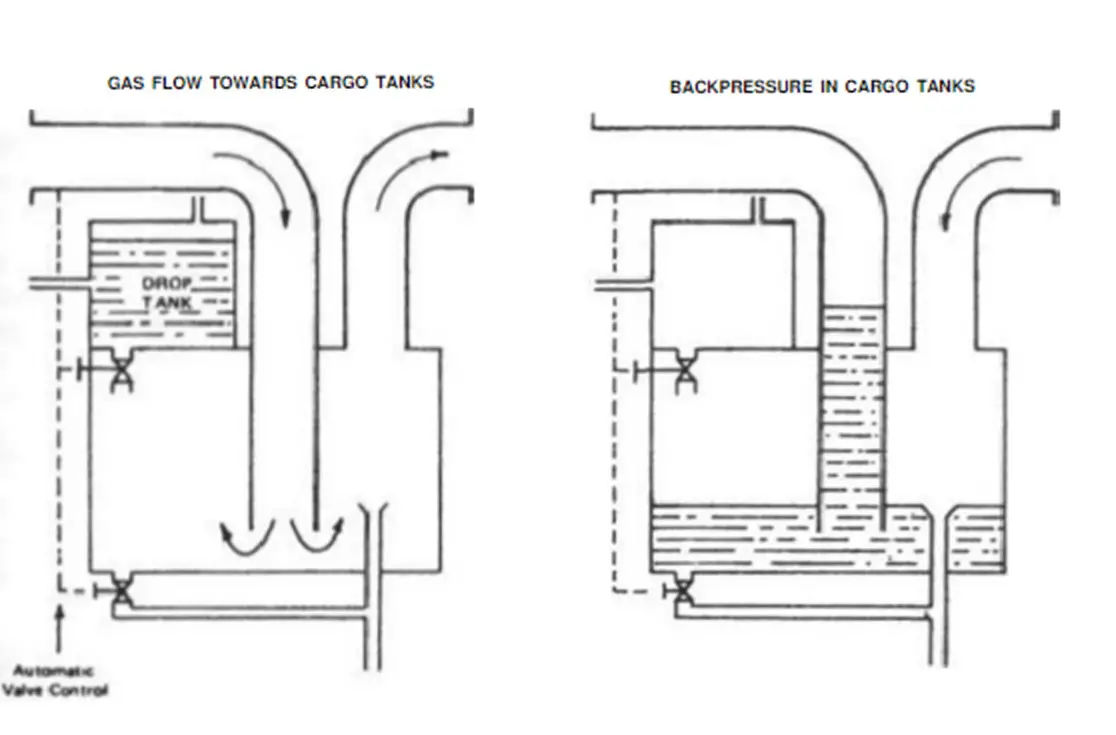

Dry type

In this type the water is drained when the inert gas plant is in operation (gas flowing to the tanks) and filled with water when the inert gas plant is either shut down or the tank pressure exceeds the inert gas blower discharge pressure. Filling and drainage are performed by automatically operated valves controlled by the levels in the water seal and drop tanks and by the operating slate of the blowers. The advantage of this type is that water carry-over is prevented. The drawback could be the risk of failure of the automatically controlled valves which may render the water seal ineffective.

*Pictures are extracts from paper copy

hi team,

Could you please contact me on below email.I want to request the quotation for Deck water seal.