General Hydrocarbon gas normally encountered in petroleum tankers cannot burn in an atmosphere containing less than approximately 11% oxygen by volume. One way to provide protection against fire or explosion in the vapour space of cargo tanks is to keep the oxygen level below that figure. This is usually achieved by using a fixed piping arrangement to blow inert gas into each cargo tank in order to reduce the air content, and oxygen content and render the tank atmosphere non-flammable. Sources of Inert Gas Possible sources of IG on tankers and combination carriers are:Uptake gas from … [Read more...]

Glossary of Terms – Petroleum Cargo Calculations

Gross Observed Volume (GOV): The total volume of all petroleum liquids and sediment and water, excluding free water, at observed temperature and pressure.Gross Standard Volume (GSV): The total volume of all petroleum liquids and sediment and water, excluding free water, corrected by the appropriate volume correction factor (VCF) for the observed temperature and API gravity, relative density, or density to a standard temperature such as 60°F or 15°C and also corrected by the applicable pressure correction factor and meter factor.Relative Density: It is defined as the ratio of the … [Read more...]

Pre-Loading Cargo Handling Procedures on Oil Tankers

Voyage Orders The vessel will usually receive voyage orders from the Charterers which will contain the following information:-Ports of loading and discharge along with draft limitations (if any) Volume / Weight to be loaded, grade or grades and Densities involved Special requirements of cargo – e.g. heating Special properties of cargo – e.g. H2SPlanning Cargo Stowage The following factors are to be considered when planning stowage of cargo as applicable:The limiting load line zone of the loaded passage and the port of destination. Draft restrictions during the … [Read more...]

Cargo Conditioning, Reliquefaction – Gas Tankers

Purpose The term Cargo Conditioning refers to the "maintaining" during the passage of:Cargo quantity without undue losses. Cargo tank pressure/temp within design limits. maintaining or altering cargo temperature as required.This is achieved by reliquefaction. Cargo conditioning may not be necessary on ships with pressure vessel tanks, depending on filling limits.If reliquefaction plant is fitted the responsible personnel should have a thorough understanding of its operational principles. When running, the plant should be monitored so that anything affecting its safety or … [Read more...]

Static Electricity / Electrostatic Hazards

Static electricity is an imbalance of electric charges within or on the surface of a material. The charge remains until it is able to move away by means of an electric current or electrical discharge. Static electricity is electricity that does not flow in a current. Static electricity generated by rubbing two nonmagnetic objects together. The friction between the two objects generates attraction because the substance with an excess of electrons transfers them to the positively-charged substance. Usually, substances that don't conduct current electricity (insulators) are good at holding a … [Read more...]

What is Load on Top (LOT)?

Not all oil pollution is caused by tankers. However, the huge volume of crude oil transported by sea has created a major problem in disposing of dirty ballast and tank washings without harming the marine environment or damaging coastal amenities. Most crude oils contain wax and other materials in solution, together with sediments, which may settle out during the voyage and form a residue with any cargo remaining after discharge (of the order of 0.2 to 0.5 per cent of the cargo carried). If discharged into the sea in heavy concentrations in the course of tank washing the residue will stay on … [Read more...]

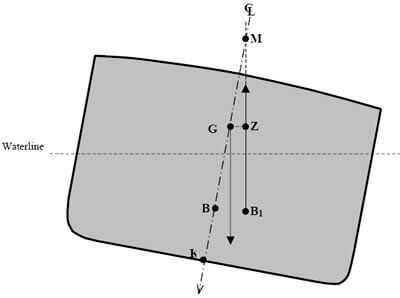

Intact Stability – Tankers

Annex I- Regulations for the Prevention of Pollution by Oil Chapter 4 - Requirements for the cargo area of oil tankers. Part A - Construction Regulation 27 - Intact stability 1 Every oil tanker of 5,000 tonnes deadweight and above delivered on or after 1 February 2002 shall comply with the intact stability criteria specified for any operating draught under the worst possible conditions of cargo and ballast loading, consistent with good operational practice, including intermediate stages of liquid transfer operations. Under all conditions, the ballast tanks shall be assumed slack..1 In … [Read more...]

Tankscopes – Tanker Instruments

Non-Catalytic Heated Filament Gas Indicators (Tankscopes) Operating Principle The sensing element of this instrument is usually a non-catalytic hot filament. The composition of the surrounding gas determines the rate of loss of heat from the filament, and hence its temperature and resistance. The sensor filament forms one arm of a Wheatstone Bridge The Initial zeroing operation balances the bridge and establishes the correct voltage across the filament, thus ensuring the correct operating temperature During zeroing, the sensor filament is purged with air or inert gas that is free from … [Read more...]

Combustible Gas Indicator or (Explosimeter) – Tanker Instruments

Principle The Combustible Gas Indicator (CGI) or Explosimeter is used to measure the volume of flammable gas in a gas/air mixture. It gives the result as a percentage of the lower flammable limit. It is used to ascertain the atmosphere in a cargo tank when planning tank cleaning in a too lean atmosphere or for evaluation of C/H gas prior to man entry, hot work or other operations.Marine Safety Appliances MSA 40 is a commonly used CCI. It works on the Catalytic Combustion Principle. A catalytic filament is heated by an electric current. A sample of the atmosphere to be tested is drawn over … [Read more...]

Types of Double Hull Tankers

Double hull tankers The double hull design has many advantages over the more traditional single-hull designs, performing better in the low-speed collision or grounding situations. Looking at 30 tanker groundings between 1969 and 1973, a study by the U.S. Coast Guard concluded that 96 percent of the spills could have been prevented with double hulls. How these monstrous tankers can so successfully avoid oil spillage is a direct outcome of their engineering and design. There are two types of double-hull ballast arrangements:The first is the "L" type arrangement, where the ballast is the … [Read more...]