General Hydrocarbon gas normally encountered in petroleum tankers cannot burn in an atmosphere containing less than approximately 11% oxygen by volume. One way to provide protection against fire or explosion in the vapour space of cargo tanks is to keep the oxygen level below that figure. This is usually achieved by using a fixed piping arrangement to blow inert gas into each cargo tank in order to reduce the air content, and oxygen content and render the tank atmosphere non-flammable. Sources of Inert Gas Possible sources of IG on tankers and combination carriers are:Uptake gas from … [Read more...]

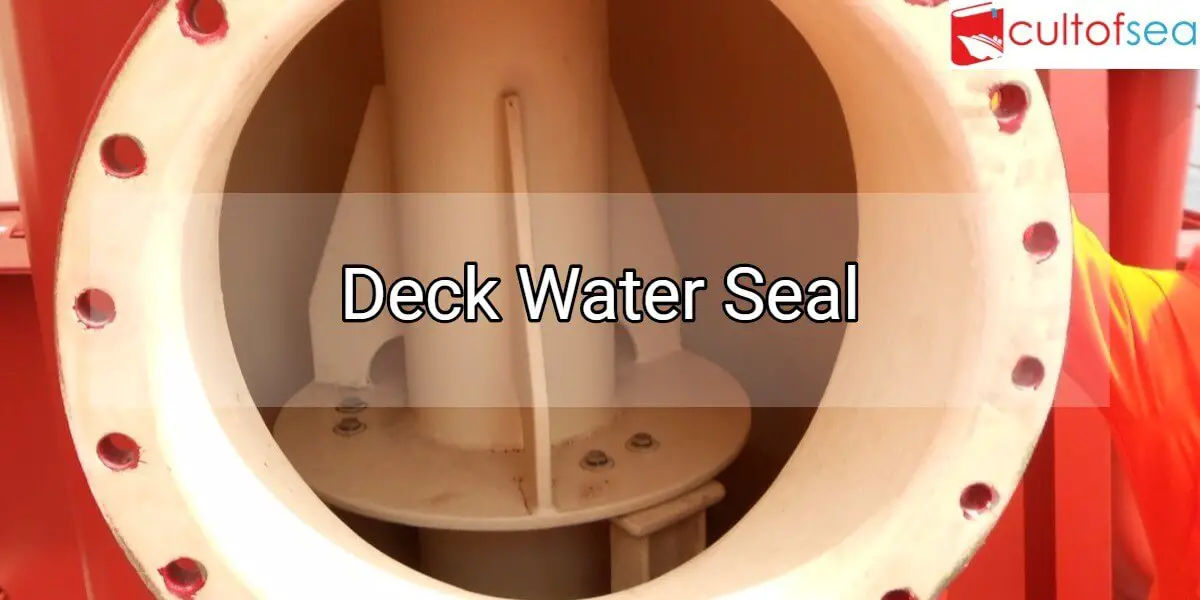

Deck Water Seal – Inert Gas System on Tankers

Deck Water Seal In an inert gas system onboard Tanker ships, Deck water seal is the principal barrier. A water seal is fitted which permits inert gas to be delivered to the deck main but prevents any backflow of cargo gas even when the inert gas plant is shut down. It is vital that a supply of water is maintained to the seal at all times, particularly when the inert gas plant is shut down. In addition, drains should be led directly overboard and should not pass through the machinery spaces.There are different designs but one of three principal types may be adopted: Wet type This is … [Read more...]