Definition

Work involving sources of ignition or temperatures sufficiently high to cause the ignition of a flammable gas mixture is termed as Hot Work. This includes any work requiring the use of welding, burning or soldering equipment, blow torches, some power-driven tools, portable electrical equipment which is not intrinsically safe or contained within an approved explosion-proof housing, and internal combustion engines.

Hot Work Permit

A document issued by a Responsible Person permitting specific Hot Work to be done during a particular time interval in a defined area. The SMS should include adequate guidance on the control of Hot Work and should be robust for compliance to deliver the expectations of ISM code and confirm that it is effective and that stated procedures are being followed.

Responsibility

Master

- The Master must satisfy himself that hot work is justifiable before granting permission for hot work to be carried out on the ship. It is the master’s responsibility to ensure that the established procedures for all hot-work are implemented and complies fully with the company requirements.

- If in port, Local port and/or terminal approval is obtained in writing prior carrying out any work.

- All flag state regulations are considered.

- Conduct a safety briefing to ensure that control measures are in place and understood & complied with to the fullest extent.

- Prepare a risk assessment with the heads of department to ensure that the environment onboard is sufficiently safe for hot-work and identify any conflicting operation carried out simultaneously.

- Issue the Work Permit just prior commencing work, monitor all safety controls are maintained throughout and cancel the permit if conditions are breached or advised by the responsible officer.

Head of Department (Chief Officer & Chief Engineer)

- Inspecting the work area and the equipment to be used for hot-work together with the person/s carrying out the job.

- Physically checking and filling-up the work permit jointly with the responsible officer and the person/s involved in the work.

- Testing the atmosphere of the work area where applicable

- Ensuring continuous effective ventilation of the work area.

- Determining that hot-work is safe to be carried out and signing the permit.

- Monitor the work is going on as per safety briefing.

- Inform the master to retract the permit if safe working conditions are breached.

- To continue monitoring the worked area for at least 30 minutes after completion of hot work or until the risk of fire no longer exists.

The person carrying out the job is responsible for:

Following the safe procedures established and for using the specified personal protective equipment.

Example of Hot Work On-Board Vessel

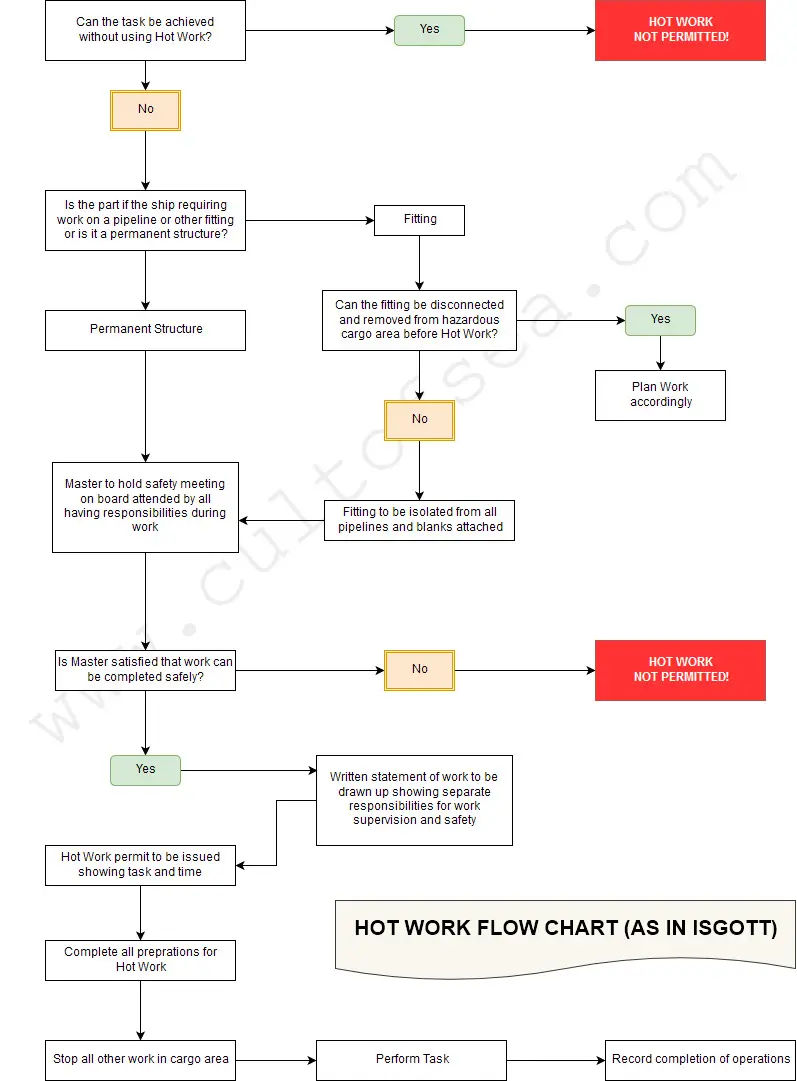

Hot Work Flow Chart (ISGOTT)

Control

Hot Work inside a Designated Space

The Designated space for hot-work onboard is allocated where it is safe to carry out such operation with hot-work permit not required to be issued. However, the duty officer on the bridge shall always be informed before the start of hot work inside a designated space. Usually, Engine Room workshop is considered as a Designated Space.

Hot Work outside a Designated Space

To prevent unauthorized hot work outside the designated hot work area, welding extension cables & portable welding machines will be controlled items and kept under lock & key in the engine room workshop locker. The master is the only person allowed to approve any hot work outside the designated hot work area with prior approval from the company.

The Hot Work Process

- The work area shall be carefully prepared and isolated before Hot Work commences.

- Fire safety precautions and fire extinguishing measures shall be reviewed. Adequate fire-fighting equipment must be prepared, laid out and ready for immediate use.

- Fire watch procedures must be established for the area of Hot Work and for adjacent spaces where the transfer of heat or accidental damage might create a hazard, e.g. damage to hydraulic lines, electrical cables, thermal oil lines, etc. The fire watch should monitor the work and take action in case of ignition of residues or paint coatings. Effective means of containing and extinguishing welding sparks and molten slag must be established.

- The work area must be adequately and continuously ventilated and the frequency of atmosphere monitoring must be established.

- When alongside a terminal, Hot Work should only be permitted in accordance with prevailing national or international regulations, port and terminal requirements.

- Personnel carrying out the work shall be adequately trained and have the competency required to carry it out safely and effectively.

- The Hot Work Permit shall be issued immediately before the work is to be performed. In the event of a delay to the start of the work, all safety measures shall be re-checked before work actually commences.

- If the conditions under which the permit has been issued should change, Hot Work must stop immediately. The permit shall be withdrawn or cancelled until all conditions and safety precautions have been checked and reinstated to allow the permit to be reissued or re-approved.

- Isolation of the work area and fire safety precautions should be continued until the risk of fire no longer exists.

Risks Involved in Carrying out Hot Work and Control Measures to be taken

| Hazard involved | Control Measures to be made |

| Inhalation hazard due to smoke generation. | – Proper PPE shall be donned at all times. – Ventilation running throughout operation (if applicable). Source for driving the ventilation fan(s) must be kept on (air compressor/fire pump) throughout the hot work operation. – Follow safe practices as per Code of Safe Working Practices for Merchant Seamen(COSWP). |

| Electric Shock. | – Approved and good condition of electric welding equipment i.e. cables, electric holder shall be used. – All electric welding equipment to be checked for insulation-Min 1 Mega ohm. – Earthing cable to be connected. |

| Eye injury | – Welding mask and safety goggles to be used. – All personnel involved in the operation shall wear safety glasses. |

| Falling from a height. Slipping/tripping depending on the location of hot work. | – Proper PPE shall be donned at all times. – Adequate non-skid shoes to be worn. – Ensure area is clear of any slipping hazard. – Safety harness shall be used where applicable. – Working aloft checklist to be completed so as to avoid any crucial points. |

| Personnel injury by falling objects. | – Whilst lowering any objects, safety lines/ buckets to be used. – All equipment and ropes to be used for the job shall be thoroughly inspected. – Prior lowering any objects, ensure that all personnel in the space are clear underneath. |

| Burns, Scalds due to contact with Hot Surfaces. | – Proper PPE shall be donned at all times. – Personnel involved in the hot work to exercise utmost care to ensure no contact is made with hot surfaces. |

| Fire/ explosion hazard. | – A fire watch shall be posted. – Fire Fighting Equipment to be ready for immediate use in the vicinity. – All elements of the hot work permit shall be followed prior commencement of hot work. – Gas checks to be carried out to ensure space is free of any combustible material. |

You may also find below interesting to read:

Leave a Reply