The spring-driven marine chronometer is a precision timepiece used aboard ship to provide accurate time for celestial observations. A chronometer differs from a spring-driven watch principally in that it contains a variable lever device to maintain even pressure on the mainspring, and a special balance designed to compensate for temperature variations.

A spring-driven Marine Chronometer

PC: BritishMuseum.org

A spring-driven chronometer is set approximately to Greenwich mean time (GMT) and is not reset until the instrument is overhauled and cleaned, usually at three-year intervals.

The difference between GMT obtained directly from a radio time signal and chronometer time (C) is carefully determined and applied as a correction to all chronometer readings.

This difference, called chronometer error (CE), is fast (F) if chronometer time is later than GMT, and slow (S) if earlier. The amount by which chronometer error changes in 1 day is called chronometer rate or variance.

A chronometer log is maintained on board to keep track of the chronometer error and the chronometer rate. An erratic rate indicates a defective instrument requiring repair.

The principal maintenance requirement is regular winding at about the same time each day. At maximum intervals of about three years, a spring-driven chronometer should be sent to a chronometer repair shop for cleaning and overhaul.

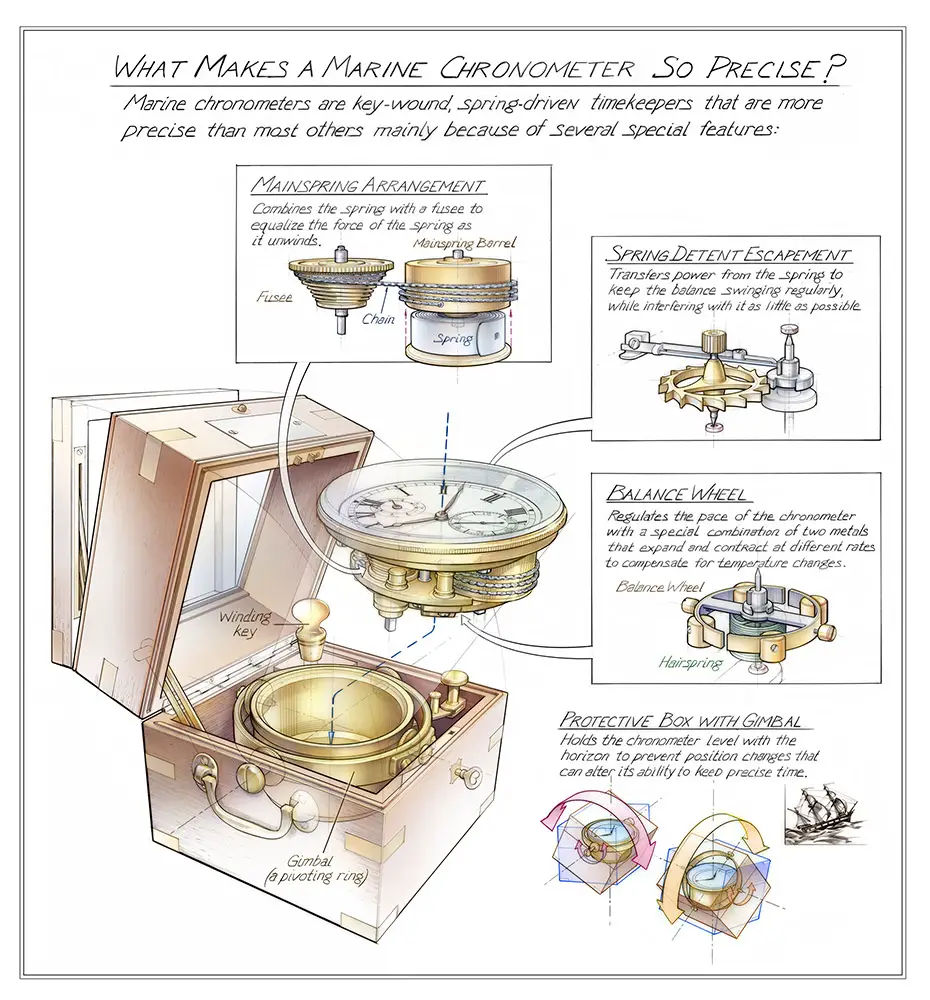

Marine chronometers are key-wound, spring driven timekeepers that are more precise than most others mainly because of several special features.

PC: timeandnavigation.si.edu

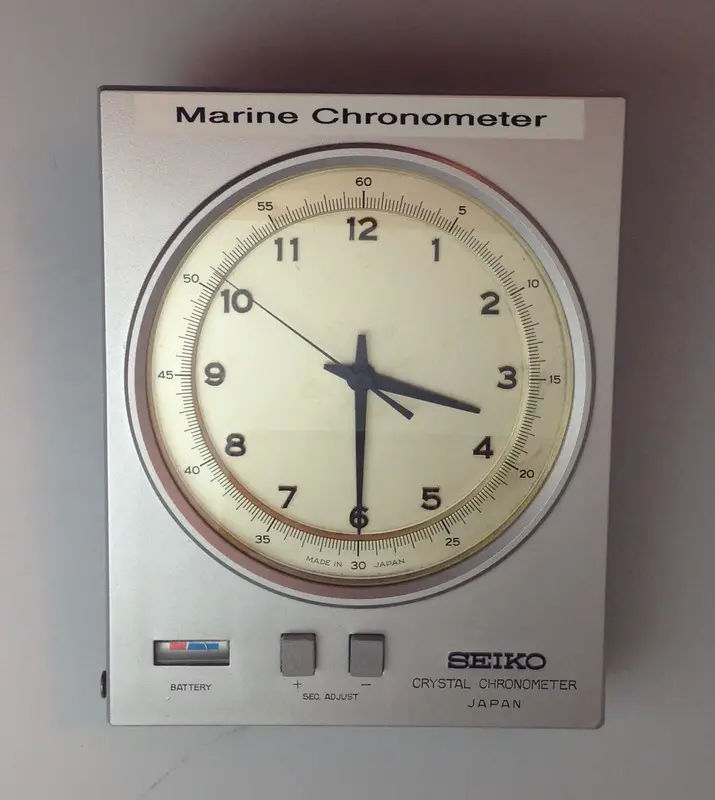

Quartz crystal marine chronometers have replaced spring-driven chronometers aboard many ships because of their greater accuracy. They are maintained on GMT directly from radio time signals. This eliminates chronometer error (CE) corrections. Should the second hand be in error by a readable amount, it can be reset electrically.

A chronometer log is maintained on board to keep track of the chronometer error if any, resetting if done, change of batteries.

The basic element for time generation is a quartz crystal oscillator. The quartz crystal is temperature compensated and is hermetically sealed in an evacuated envelope. A calibrated adjustment capability is provided to adjust for the ageing of the crystal.

The chronometer is designed to operate for a minimum of 1 year on a single set of batteries. A good marine chronometer has a built-in push button battery test meter.

The meter face is marked to indicate when the battery should be replaced. The chronometer continues to operate and keep the correct time for at least 5 minutes while the batteries are changed. The chronometer is designed to accommodate the gradual voltage drop during the life of the batteries while maintaining accuracy requirements.

A quartz crystal Marine Chronometer

Sample Chronometer Error Log

| Date / SMT | Time Signal Station / Freq | GMT hh mm ss | Chron Time hh mm ss | Error mm ss S / F | Rate mm ss / day |

HELLO SIR,

IT IS A BEAUTIFUL ARTICLE ABOUT CHRONOMETERS.IT IS GREAT INFORMATION FOR MARINERS.

I HAVE A SMALL CLARIFICATION ABOUT QUARTZ MARINE CHRONOMETER.IF THERE IS A QUARTZ MARINE CHRONOMETER ONBOARD THEN THERE IS NO NEED TO DO FIND THE CHRONOMETER ERROR MANUALLY USING ALRS VOLUME 2 AND RADIO TIME SIGNALS.

IS THAT AFFIRMATIVE? KINDLY CLARIFY

This is a great article about chronometers.I have a small doubt that if there is a quartz chronometer onboard then there is no need for the officer on watch to check chronometer errors manually using ALRS Volume 2 and radio time signals ?

Kindly clear my doubt.